Processo de usinagem em lote CNC para peças de alumínio

Como líder CNC machining service provider, AOOM Technologies specializes in high-volume aluminum component manufacturing with precision and efficiency. This article will explore the critical aspects of CNC batch machining for aluminum parts, addressing the key concerns of procurement managers and engineers.

Entendendo a usinagem em lote CNC para alumínio

A usinagem em lote refere-se à produção de componentes de alumínio idênticos em quantidades predeterminadas usando a tecnologia CNC. Na AOOM, empregamos máquinas CNC de eixo avançado 3/4/5, capazes de manusear ligas de alumínio das séries 100 a 700, garantindo uma precisão dimensional de ± 0,01 mm.

Principais etapas do processo

1. Material Preparation: Selection of appropriate aluminum grade based on mechanical requirements

2. Fixture Design: Custom workholding solutions for batch consistency

3. Toolpath Optimization: CAM programming for maximum material removal rates

4. Quality Control: In-process inspection with CMM and surface roughness testers

Vantagens do nosso serviço de usinagem em lote

• Cost-effective production for quantities from 50-10,000+ units

• 15-30% faster cycle times through optimized tooling strategies

• Dedicated production cells for aluminum-specific machining

• ISO 9001-certified quality management system

Aplicações da Indústria

Nossas capacidades de usinagem em lote servem:

- Aerospace: Structural components and housings

- Automotive: Engine parts and transmission elements

- Electronics: Heat sinks and enclosures

- Medical: Instrumentation components

Com mais de 12 anos de experiência em usinagem de alumínio, a AOOM Technologies oferece CNC batch machining solutions that balance precision, speed, and cost-efficiency. Contact our engineering team today to discuss your specific project requirements.

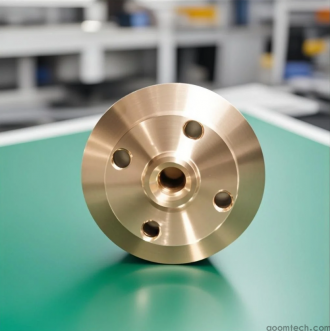

Processo de usinagem CNC de latão

Processo de usinagem CNC de latão

Processamento de peças mecânicas de precisão CNC: qual empre

Processamento de peças mecânicas de precisão CNC: qual empre

Processo de usinagem de parafusos CNC

Processo de usinagem de parafusos CNC

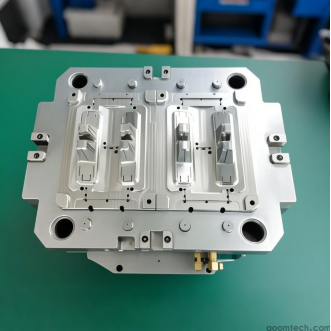

Processamento de moldes CNC: Considerações-chave para result

Processamento de moldes CNC: Considerações-chave para result