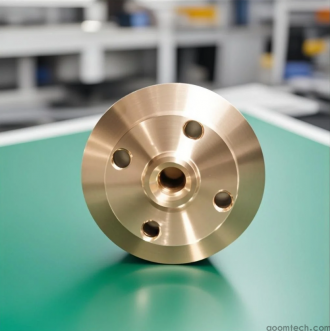

Processo de usinagem de parafusos CNC

Na fabricação de precisão, CNC bolt machining process stands as a critical operation for industries requiring high-tolerance fasteners. As a leading CNC machining service provider, AOOM Technology delivers exceptional bolt manufacturing solutions tailored to aerospace, automotive, and industrial applications.

Entendendo a usinagem de parafusos CNC

O CNC bolt machining process involves computer-controlled lathes or milling machines transforming raw metal bars into precision bolts through sequential operations including turning, threading, head forming, and surface finishing. Our 5-axis CNC machines achieve ±.005mm tolerances, ensuring perfect thread engagement and load distribution.

Principais vantagens da nossa produção de parafusos CNC

1. Material Versatility: We machine bolts from stainless steel, titanium, aluminum, and exotic alloys

2. Thread Precision: ACME, UN, metric, and custom thread profiles with certified accuracy

3. Surface Treatments: Optional plating, anodizing, or passivation for corrosion resistance

4. Batch Flexibility: From prototype quantities to 100,000+ production runs

Especificações técnicas

Nossa CNC bolt machining process accommodates:

• Diameter range: M1.6 to M64

• Length-to-diameter ratios up to 12:1

• Head types: Hex, socket, flange, and custom designs

• Compliance with ISO 898, ASME B18.2, and DIN standards

Por que escolher a tecnologia AOOM?

Com mais de 15 anos de experiência em usinagem CNC, combinamos tornos avançados do tipo suíço com controle de qualidade rigoroso (incluindo 100% de medição de rosca) para fornecer parafusos com propriedades mecânicas perfeitas. Nossos engenheiros otimizam todos os parâmetros de usinagem - desde velocidades de corte até caminhos de ferramenta - garantindo máxima resistência à tração e resistência à fadiga.

Solicite uma revisão gratuita do projeto em www.aoomtech.com to experience precision bolt manufacturing that eliminates assembly issues and reduces total fastener costs.

Processo de usinagem CNC de latão

Processo de usinagem CNC de latão

Processamento de peças mecânicas de precisão CNC: qual empre

Processamento de peças mecânicas de precisão CNC: qual empre

Processo de usinagem de parafusos CNC

Processo de usinagem de parafusos CNC

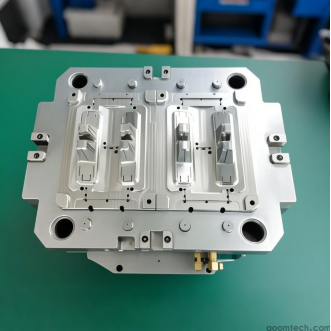

Processamento de moldes CNC: Considerações-chave para result

Processamento de moldes CNC: Considerações-chave para result