Citação de usinagem de precisão CNC

Ao terceirizar CNC precision machining services, understanding the factors influencing CNC machining quotes is critical for procurement managers and engineers. AOOM Technology, a trusted CNC machining manufacturer, breaks down the key elements that determine pricing and how to optimize costs without compromising quality.

Fatores que afetam a cotação de usinagem CNC

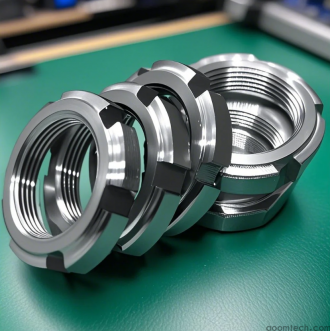

1. Material Costs: Raw material type (e.g., aluminum, stainless steel, titanium) significantly impacts pricing due to varying market prices and machinability. 2. Part Complexity: Intricate designs with tight tolerances or thin walls require advanced tooling and longer machining time. 3. Production Volume: Bulk orders often reduce unit costs through economies of scale. 4. Surface Finishing: Additional processes (anodizing, polishing) add to the total quote. 5. Lead Time: Urgent orders may incur expedited fees.

Como o AOOM otimiza seus custos de usinagem CNC

A tecnologia AOOM aproveita máquinas CNC avançadas de 5 eixos e ferramentas internas para minimizar o desperdício e acelerar a produção. Nossos engenheiros fornecem Design for Manufacturability (DFM) feedback to simplify part geometry without sacrificing functionality, reducing machining hours and material usage.

Modelo de precificação transparente

Oferecemos cotação on-line instantânea para projetos padrão por meio de nossa plataforma (www.aoomtech.com), com detalhamentos detalhados para solicitações personalizadas. Ao contrário dos concorrentes, o AOOM inclui custos de pós-processamento antecipados para evitar taxas ocultas.

Para obter uma cotação de usinagem CNC personalizada, envie seus arquivos CAD para AOOM’s quotation system or contact our engineering team for high-mix, low-volume prototyping solutions.

Citação de usinagem de aço inoxidável CNC: fatores que afeta

Citação de usinagem de aço inoxidável CNC: fatores que afeta

Fabricação e processamento de produtos CNC Fabricante

Fabricação e processamento de produtos CNC Fabricante

Peças médicas de usinagem CNC

Peças médicas de usinagem CNC

Fabricante de usinagem personalizada não padrão CNC

Fabricante de usinagem personalizada não padrão CNC