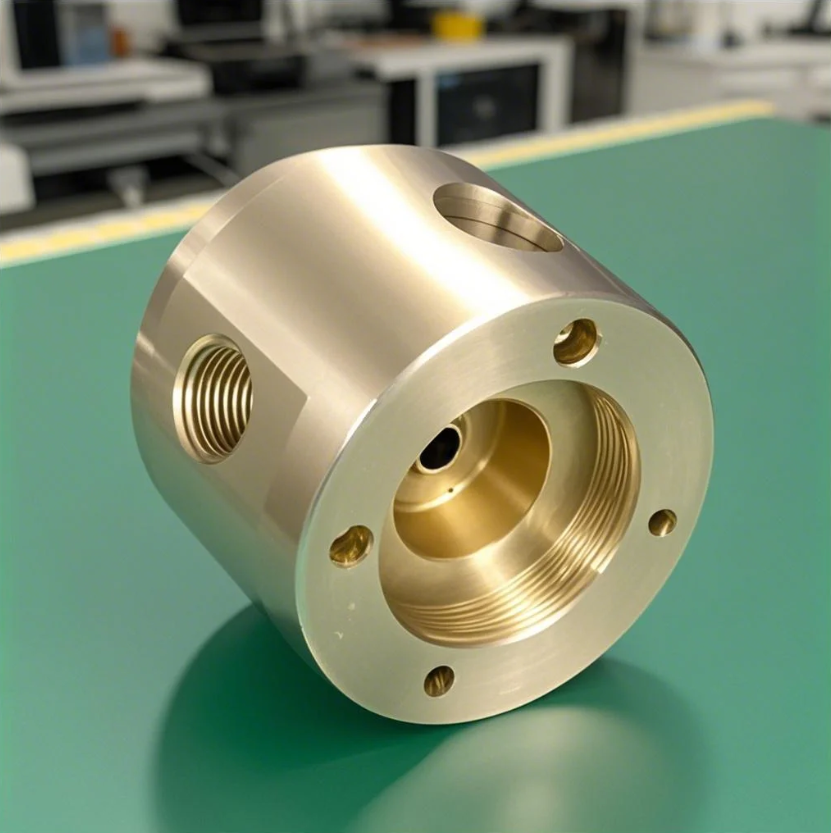

Латунь с ЧПУ: прецизионное производство для долговечных компонентов

Когда дело доходит до brass CNC machining, manufacturers demand a combination of precision, material expertise, and cost-efficiency. At AOOM, we specialize in transforming brass alloys into high-performance components for industries ranging from plumbing to aerospace. This guide explores the technical nuances of brass machining and how our capabilities deliver unmatched results.

Почему выбирают латунь для обработки с ЧПУ?

Латунь (сплав меди и цинка) обеспечивает исключительную обрабатываемость, коррозионную стойкость и электропроводность. Его самосмазывающие свойства снижают износ инструмента во время CNC machining, making it ideal for valves, fittings, and decorative hardware. Our ISO 9001-certified facility optimizes feed rates and tool paths specifically for brass to prevent material galling.

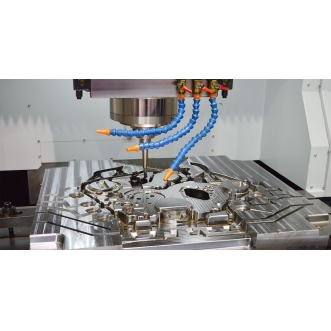

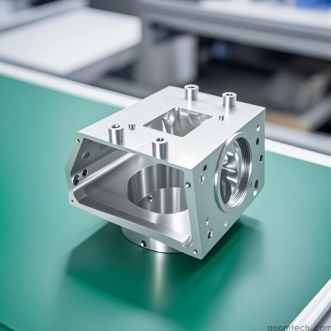

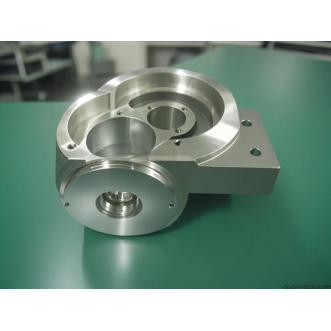

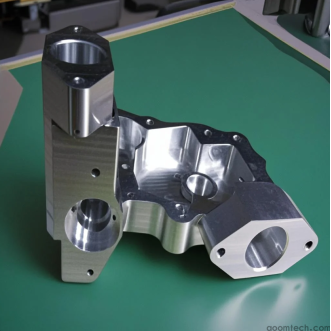

Латунный обрабатывающий процесс с ЧПУ AOOM

1. Material Selection: We stock C36000 (free-cutting brass), C26000 (cartridge brass), and other grades to match your project requirements.

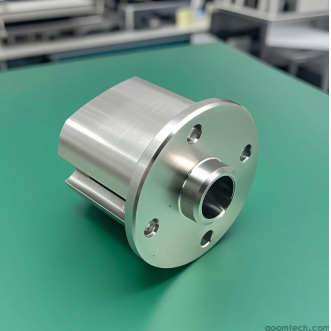

2. Precision Turning/Milling: 5-axis CNC machines achieve ±.005mm tolerances with mirror-like surface finishes.

3. Secondary Processing: Deburring, polishing, or plating (nickel/chrome) services available.

Отрасли, которые мы обслуживаем с латунными компонентами

• Electronics: RF connectors, terminals (benefiting from brass's EMI shielding)

• Automotive: Fuel system components, bushings

• Architecture: Custom decorative fixtures with intricate detailing

В отличие от дженерика CNC machining suppliers, AOOM provides DFM feedback to optimize your brass part designs for manufacturability and cost reduction. Our 24/7 production capacity and strict QC protocols ensure on-time delivery of defect-free components.