5-осевая CNC подвергая механической обработке цитата

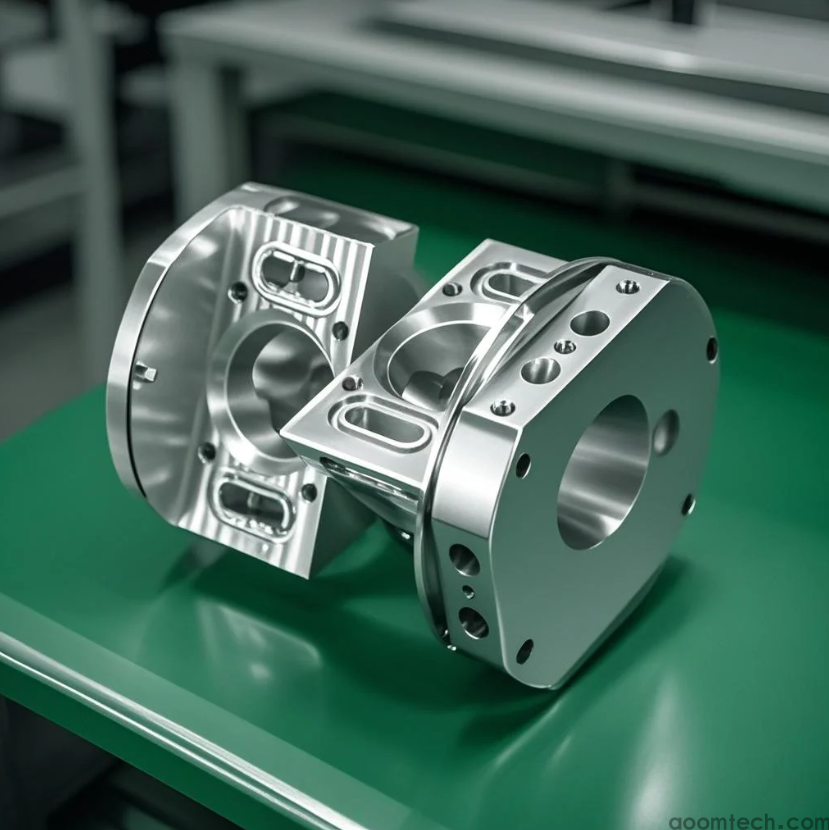

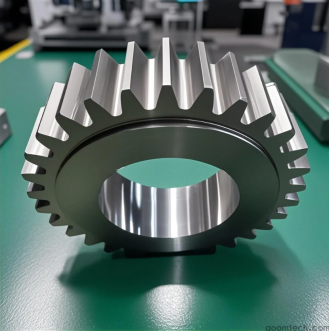

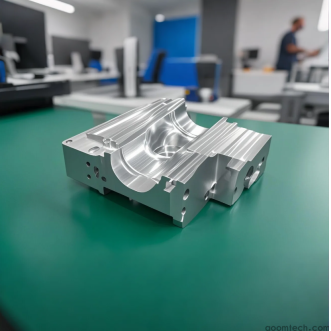

При поиске 5-axis CNC machining services, understanding the quotation breakdown is critical for procurement managers and engineers to make cost-effective decisions without compromising precision. As a leading CNC machining manufacturer, AOOM Technology decodes the pricing factors to ensure transparency for our global clients.

Ключевые факторы, влияющие на стоимость 5-осевой обработки с ЧПУ

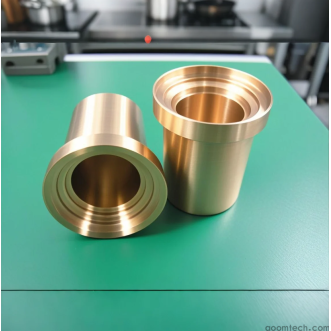

1. Material Costs: Aerospace aluminum (6061/7075), titanium, or PEEK require different tooling strategies and machine time.

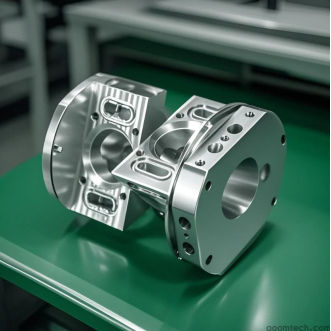

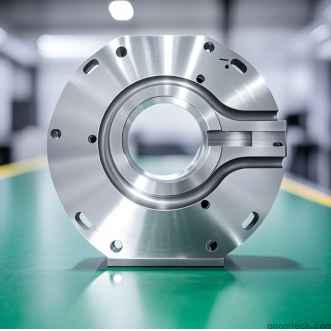

2. Part Complexity: Undercuts, thin walls, and tight tolerances (±.01mm) increase programming and machining time.

3. Surface Finishing: Additional processes like anodizing or mirror polishing add post-processing costs.

4. Order Volume: Batch production typically reduces per-unit costs through optimized tool paths.

Конкурентные преимущества AOOM в котировках

• In-house machining eliminates subcontractor markups

• 15+ years of experience in complex part optimization

• ISO 9001-certified quality control with full traceability

• Real-time project tracking through our digital portal

Как получить точные котировки быстрее

Укажите эти данные в вашем запросе:

3D CAD files (STEP/IGES preferred)

Material specifications

Quantity requirements

Surface treatment needs

Delivery timeline

Посетить AOOM Technology to submit your technical drawings for instant quotation analysis. Our engineering team responds within 4 business hours with DFM suggestions to potentially reduce your costs by up to 30%.