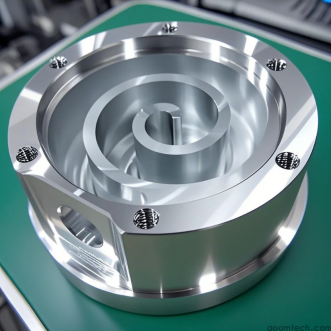

CNC presný proces obrábania výrobkov

Ako vedúci # CNC Precision Product Machining Process specialist, AOOM Technologies delivers unmatched precision manufacturing solutions for industries requiring micron-level accuracy. Our ISO-certified facility combines advanced machinery with decades of technical expertise to transform raw materials into high-performance components.

Veda za presným CNC obrábaním

Skutočné presné obrábanie začína pochopením správania materiálu. Naši technici analyzujú kovové zliatiny, technické plasty a kompozitné materiály na molekulárnej úrovni s cieľom určiť optimálne # CNC Precision Product Machining Process parameters. This scientific approach ensures dimensional stability even for parts with tolerances as tight as ±.005mm.

Kľúčové výhody nášho presného procesu

1. Multi-Axis Synchronization : 5-axis simultaneous machining eliminates secondary operations

2. Thermal Compensation : Real-time temperature monitoring prevents thermal deformation

3. Surface Integrity Control : Proprietary toolpath strategies achieve Ra .2μm finishes

4. Digital Twin Verification : All programs undergo virtual machining before production

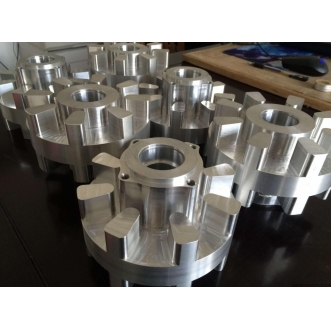

Špecifické priemyselné aplikácie

Náš # CNC Precision Product Machining Process serves critical sectors including:

- Aerospace: Turbine blades with cooling channels

- Medical: FDA-compliant surgical instruments

- Automotive: Fuel injection components

- Electronics: EMI-shielding enclosures

Prečo si vybrať presné obrábanie AOOM?

Na rozdiel od štandardných CNC obchodov implementujeme protokoly vojenskej kvality:

• In-process CMM inspection every 5 parts

• Material traceability documentation

• On-site metallurgical lab for material verification

• Dedicated engineering support throughout product lifecycle

Objavte, ako môžu naše riešenia precízneho obrábania zvýšiť výkon vášho produktu. Contact AOOM Technologies for a free design-for-manufacturability analysis today.

Aký je cenový rozsah CNC obrábaných dielov (hliník, nehrdzav

Aký je cenový rozsah CNC obrábaných dielov (hliník, nehrdzav

Ktorú CNC obrábaciu spoločnosť si vybrať? Analýza 5 základný

Ktorú CNC obrábaciu spoločnosť si vybrať? Analýza 5 základný

Metódy presného riadenia CNC obrábania a proces CNC obrábani

Metódy presného riadenia CNC obrábania a proces CNC obrábani

CNC obrábanie z nehrdzavejúcej ocele: Ako nastaviť parametre

CNC obrábanie z nehrdzavejúcej ocele: Ako nastaviť parametre