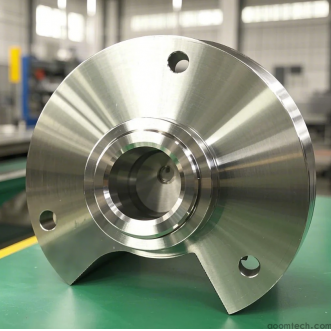

CNC dávkové obrábanie proces pre hliníkové diely

Ako vedúci poskytovateľ služieb CNC obrábania spoločnosť AOOM Technologies sa špecializuje na výrobu veľkých objemov hliníkových komponentov s presnosťou a účinnosťou. Tento článok skúma rozhodujúce aspekty CNC dávkového obrábania pre hliníkové diely a zameriava sa na hlavné záliby manažérov zásobovania a inžinierov.

Pochopenie CNC dávkové obrábanie pre hliník

Dávkové obrábanie sa týka výroby identických hliníkových komponentov vo vopred určených množstvách pomocou CNC technológie. V spoločnosti AOOM využívame pokročilé CNC stroje s 3/4/5 osou, ktoré dokážu manipulovať s hliníkovými zliatinami od série 100 do série 700, čo zabezpečuje rozmerovú presnosť v rozmedzí ± 0,01 mm.

Kľúčové kroky procesu

1. Priprava materiálu: Výber vhodnej triedy hliníka na základe mechanických požiadaviek 2. Návrh upevnenia: Prispôsobené riešenia upevnenia pre konzistenciu dávky 3. Optimalizácia cesty nástroja: CAM programovanie pre maximálne rýchlosti odstraňovania materiálu 4. Kontrola kvality: Kontrola počas procesu pomocou CMM a testrovateľov drsnosti povrchu

Výhody našej dávkovej obrábacej služby

• Nákladovo efektívna výroba pre množstvá od 50 - 10 000+ jednotiek • O 15 - 30 % rýchlejší cyklický čas prostredníctvom optimalizovaných stratégií nástrojovania • Vyhradené výročné bunky pre špecifické obrábanie hliníka • ISO 9001 - certifikovaný systém riadenia kvality

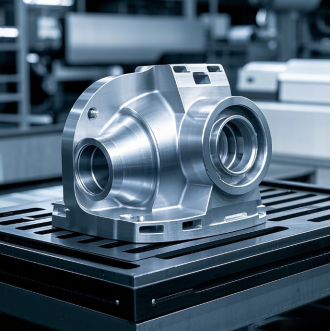

Priemyselné aplikácie

Naše schopnosti dávkového obrábania slúžia:

- Leteckému a kozmickému priemyslu: Štrukturálnym komponentom a uzatiaľovaniam - Automobilovému priemyslu: Komponentom motoru a prvkom prevodu - Elektronike: Chladiace riadičom a uzatiaľovaniam - Lekárstvu: Komponentom inštrumentácie

S viac ako 12 rokmi skúseností s obrábaním hliníka poskytuje spoločnosť AOOM Technologies spoľahlivé riešenia CNC dávkového obrábania, ktoré vyvážajú presnosť, rýchlosť a nákladovú účinnosť. Kontaktujte náš inžiniersky tím dnes a diskutujte o vašich špecifických požiadavkách projektu.

CNC obrábanie Factory: Ako si vybrať spoľahlivého partnera

CNC obrábanie Factory: Ako si vybrať spoľahlivého partnera

Ako si vybrať výrobcu CNC obrábania kovov? 6 tipov, ktoré vá

Ako si vybrať výrobcu CNC obrábania kovov? 6 tipov, ktoré vá

CNC sústružnícke kombinované obrábanie: efektívny a presný n

CNC sústružnícke kombinované obrábanie: efektívny a presný n

CNC bočné obrábanie umiestnenie: 5 kľúčových tipov na riešen

CNC bočné obrábanie umiestnenie: 5 kľúčových tipov na riešen