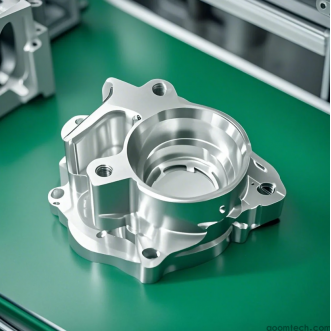

Malé diely CNC obrábanie proces

Ako profesionál small parts CNC machining service provider, AOOM Technology specializes in manufacturing high-precision components for various industries. This article will explore the technical process, quality control measures, and our competitive advantages in delivering exceptional machining solutions.

Pochopenie malých dielov CNC obrábanie

CNC obrábanie malých dielov sa vzťahuje na výrobu miniatúrnych komponentov s malými toleranciami (zvyčajne ± 0,005 mm alebo lepšie) pomocou počítačom riadeného zariadenia. Tieto diely často slúžia kritickým funkciám v priemyselných odvetviach, ako je letecký a kozmický priemysel, lekárske prístroje, elektronika a automobilové aplikácie.

Kľúčové technické hľadiská

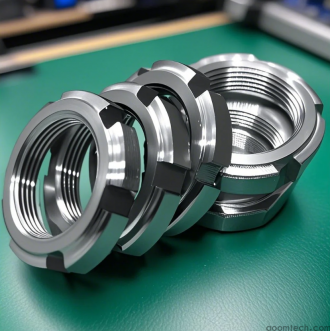

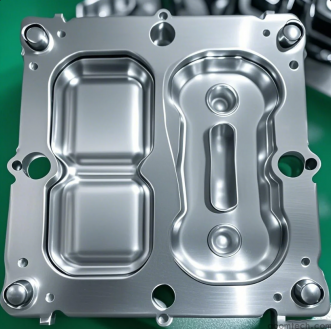

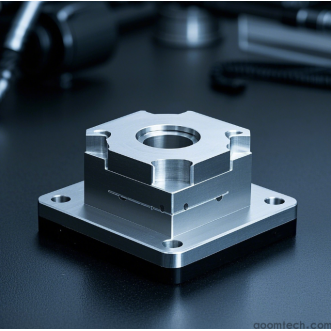

1. Material Selection: We machine various materials including aluminum alloys, stainless steel, titanium, brass, and engineering plastics

2. Precision Requirements: Our 5-axis CNC machines achieve surface finishes up to Ra .4μm

3. Production Volume: Capable of handling prototypes (1-100 pieces) to mass production (10,000+ units)

4. Secondary Operations: Offering complete solutions including deburring, anodizing, plating, and heat treatment

Prečo si vybrať AOOM pre obrábanie malých dielov?

1. Advanced Equipment: 42 CNC machining centers with Swiss-type lathes for micro-machining

2. Quality Assurance: ISO 9001 certified with complete inspection equipment including CMM

3. Technical Expertise: 15+ years experience in small parts CNC machining

4. Fast Turnaround: Standard lead time of 7-15 days with expedited options available

Aplikácie našich opracovaných malých dielov

Naše presné komponenty sú široko používané v:

- Medical implants and surgical instruments

- Connectors and enclosures for electronics

- Watch components and jewelry findings

- Automotive fuel injection systems

- Aerospace fasteners and fittings

Navštíviť AOOM Technology to learn more about our capabilities or request a free project evaluation from our engineering team.