CNC-bearbetning av aluminiumdelar: Process och applikationer

Som ledande CNC machining aluminum parts specialist, AOOM Technologies delivers precision-engineered solutions for industries demanding high-performance metal components. This guide explores the technical process and competitive advantages of our aluminum machining services.

Varför välja aluminium för CNC-bearbetning?

Aluminiumlegeringar (6061, 7075, etc.) erbjuder exceptionella machinability-to-strength förhållanden, vilket gör dem idealiska för flyg-, fordons- och elektronikapplikationer. Vår CNC machining processes maintain ±.005" tolerances while optimizing production efficiency.

Vår 6-stegs aluminiumbearbetningsprocess

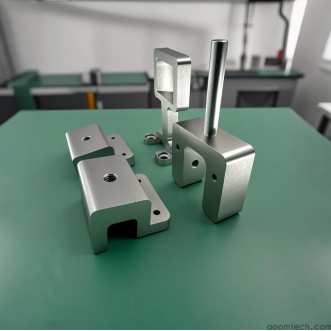

1. Material Selection: Recommending optimal alloys based on stress/weight requirements

2. CAD/CAM Programming: Converting designs into machine instructions

3. Fixture Design: Ensuring stability during high-speed cutting

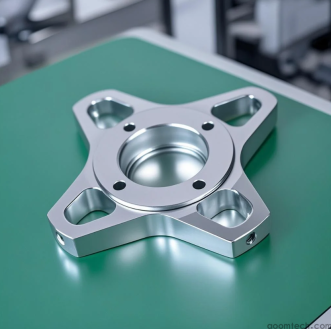

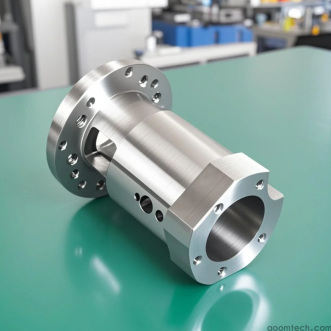

4. Precision Machining: 3/4/5-axis milling and turning operations

5. Surface Finishing: Anodizing, polishing, or coating applications

6. Quality Inspection: CMM verification and ISO 9001 documentation

Tekniska fördelar hos AOOM

• 50 + CNC-maskiner med automatiska verktygsbytare

• Dedicated aluminum machining centers with high-pressure coolant

• Aluminum-specific tooling to prevent galling and burrs

• Prototype to mass production capabilities (1-100,000+ units)

Kontakta vårt ingenjörsteam på AOOM Technologies for DFM analysis and instant quoting on your aluminum CNC projects.