CNC鋳鉄加工プロセスの流れ

CNC鋳鉄加工の理解

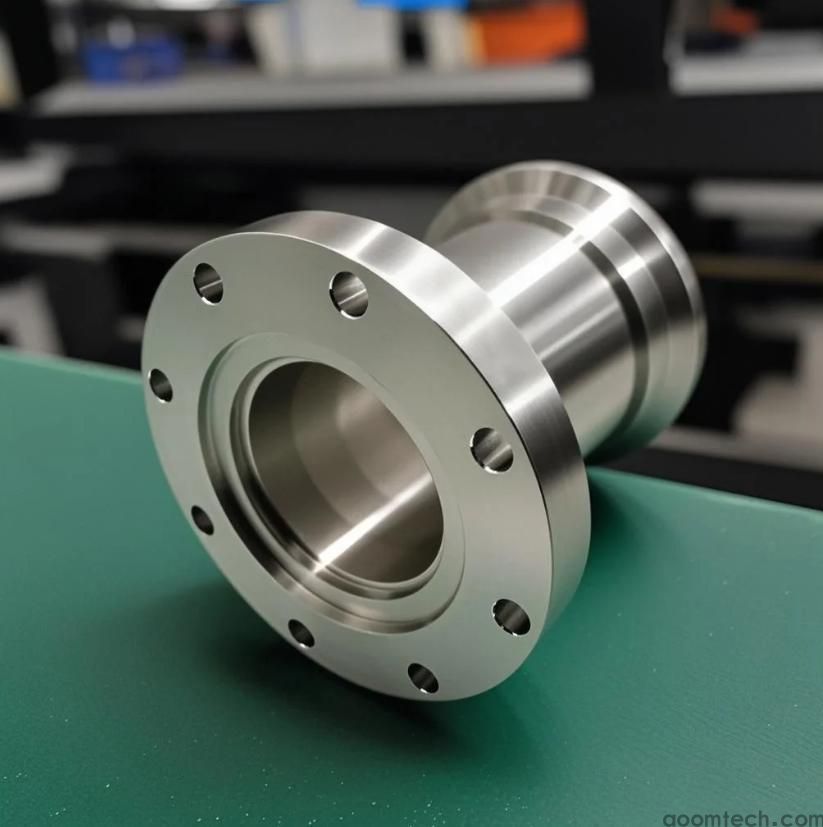

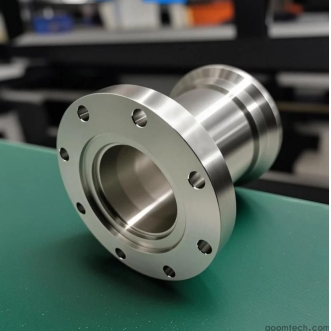

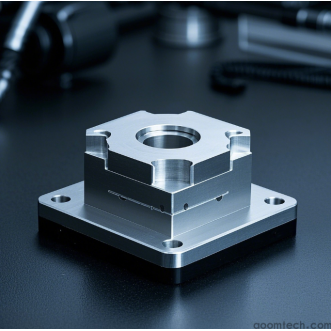

CNC鋳鉄マシニング 精密な制御と専門知識が必要な専門的な製造過程です。高強度で耐摩耗性のある材料である鋳鉄は、CNC加工において独自の課題と機会を提供します。AOOMテクノロジーズでは、自動車から重機までの産業において、優れた結果を提供するために、この過程を完成させました。

CNC鋳鉄加工プロセスの主なステップ

完全な CNC machining process for cast iron involves several critical stages:

1. Material Selection: Choosing the right grade of cast iron (gray, ductile, or malleable) based on application requirements.

2. Workpiece Preparation: Proper fixturing and alignment to ensure stability during machining.

3. Tool Selection: Using carbide or CBN tools specifically designed for cast iron's abrasive nature.

4. Machining Parameters: Optimizing cutting speeds, feed rates, and depth of cut to prevent tool wear.

5. Coolant Application: Implementing appropriate cooling strategies to manage heat and extend tool life.

最適な結果を得るための技術的考慮事項

成功した cast iron CNC machining requires attention to several technical factors:

- Vibration Control: Cast iron's damping properties help, but proper machine rigidity is still essential.

- Chip Management: Cast iron produces short, brittle chips that require efficient removal systems.

- Surface Finish: Achieving desired surface quality through proper tool path strategies.

- Dimensional Accuracy: Accounting for potential material movement during machining.

CNC鋳鉄プロジェクトにAOOM Technologiesを選ぶ理由

CNC鋳鉄加工における当社の専門知識は、私たちを区別します:

- Advanced Equipment: State-of-the-art CNC machines capable of handling cast iron's demands.

- Process Optimization: Years of experience fine-tuning parameters for different cast iron grades.

- Quality Assurance: Rigorous inspection protocols to ensure every part meets specifications.

- Turnkey Solutions: From design assistance to final finishing, we handle all aspects of production.

次の鋳鉄加工プロジェクトでは、AOOM Technologiesが精度、信頼性、そして優れた価値を提供します。当社の能力の詳細については、当社のウェブサイトhttps://www.aoomtech.com/をご覧ください。

CNCプロフェッショナルハードウェア加工メーカー

CNCプロフェッショナルハードウェア加工メーカー

CNC鋳鉄加工プロセスの流れ

CNC鋳鉄加工プロセスの流れ

CNC機械はいかに部品を分けますか。

CNC機械はいかに部品を分けますか。

CNC精密加工サプライヤー

CNC精密加工サプライヤー