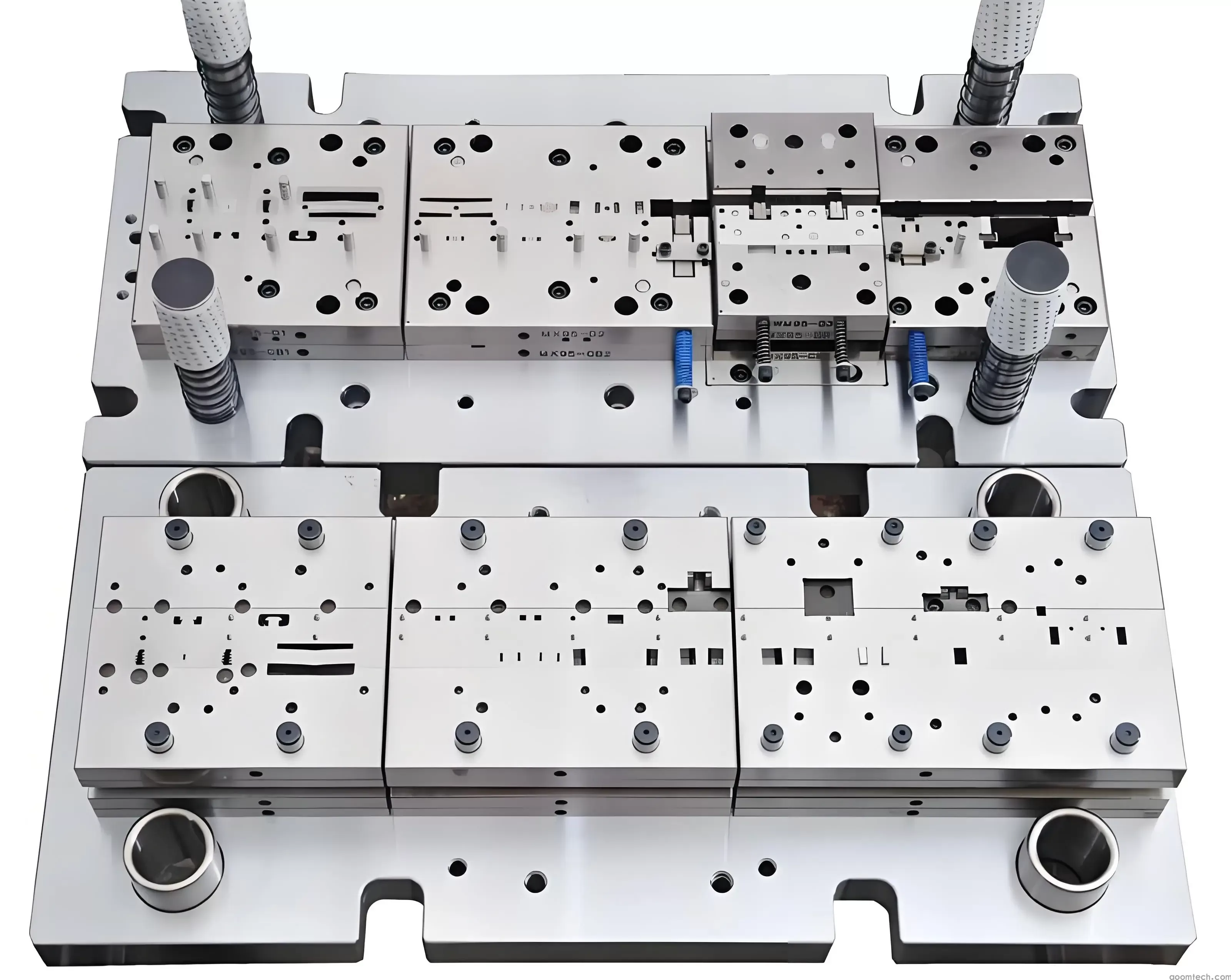

CNC Mold Machining Precautions

As a leading CNC machining service provider, AOOM Technology understands the critical aspects of mold manufacturing. This guide outlines essential precautions to ensure precision and longevity in CNC mold processing.

Material Selection Considerations

Choosing the right mold material directly impacts machining outcomes. For high-precision molds, we recommend hardened tool steels (H13, P20) or tungsten carbide. At AOOM, our material database includes 50+ certified alloys with detailed machinability parameters to guide your selection.

Toolpath Optimization Strategies

Proper toolpath planning prevents common mold defects. Our engineers employ:

- Adaptive clearing for complex cavities

- Rest machining techniques for fine details

- Trochoidal milling for hardened materials

This approach reduces tool wear by 40% compared to conventional methods.

Coolant System Management

Effective temperature control is crucial for dimensional stability. We implement:

- High-pressure through-tool coolant (100+ psi)

- Variable nozzle positioning systems

- Real-time thermal monitoring

Surface Finish Requirements

Mold surface quality affects product ejection and lifespan. Our CNC mold machining achieves Ra .2μm finishes through:

- Precision ball-nose end milling

- Multi-axis contouring

- Micro-polishing protocols

Quality Verification Process

Every AOOM machined mold undergoes:

- On-machine probing (accuracy: ±.005mm)

- 3D optical scanning

- Production simulation testing

Our ISO 9001-certified system ensures consistent results across production batches.

With 15+ years of mold manufacturing experience, AOOM Technology delivers reliable CNC machining solutions for injection molds, die casting molds, and stamping dies. Contact our engineering team at www.aoomtech.com for customized technical support.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F