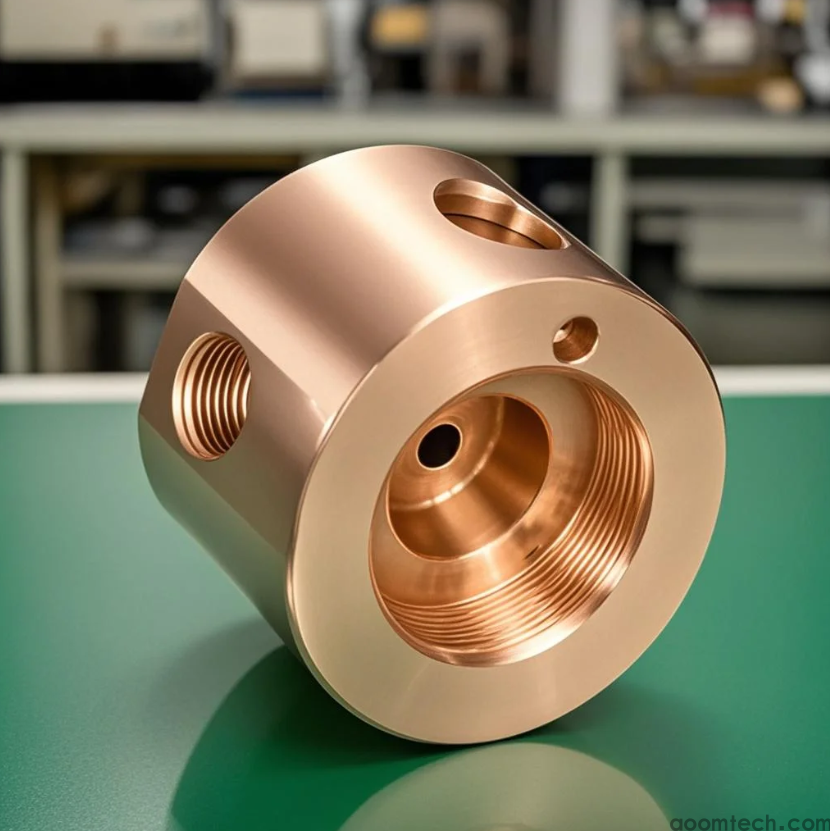

CNC Copper Parts Processing: How to Choose the Right Manufacturer

When sourcing CNC copper parts processing services, manufacturers and engineers face critical decisions that impact product quality, lead times, and cost-efficiency. As an ISO-certified CNC machining specialist, AOOM Technology offers expert solutions for precision copper components across industries.

Key Considerations for CNC Copper Machining

Copper's unique properties (excellent conductivity, thermal resistance, and malleability) demand specialized machining expertise. AOOM's technical team addresses these challenges through:

- Dedicated copper-grade tooling to prevent material galling

- Optimized coolant strategies for chip control

- Precision fixturing for thin-walled components

- Surface finish options from Ra .8μm to mirror polishing

AOOM's Advanced Capabilities

Our 15,000㎡ facility features 42 multi-axis CNC centers with .005mm repeatability, specifically configured for copper parts manufacturing:

- 5-axis simultaneous machining for complex geometries

- Swiss-type lathes for precision turned components

- In-process inspection with CMM and optical comparators

- Electroplating and passivation finishing options

Industry-Specific Solutions

We serve demanding applications including:

- Electrical: Busbars, connectors, and heat sinks

- Automotive: Sensor components and bearing cages

- Medical: Sterilizable surgical instrument parts

- Industrial: Wear-resistant bushings and valves

With 200+ successful copper machining projects annually, AOOM combines material science expertise with advanced manufacturing technology to deliver components that meet ASME Y14.5 standards. Our engineers provide DFM analysis within 24 hours of RFQ submission.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F