How to Process Hard Materials with CNC Machining

Understanding CNC Hard Material Machining

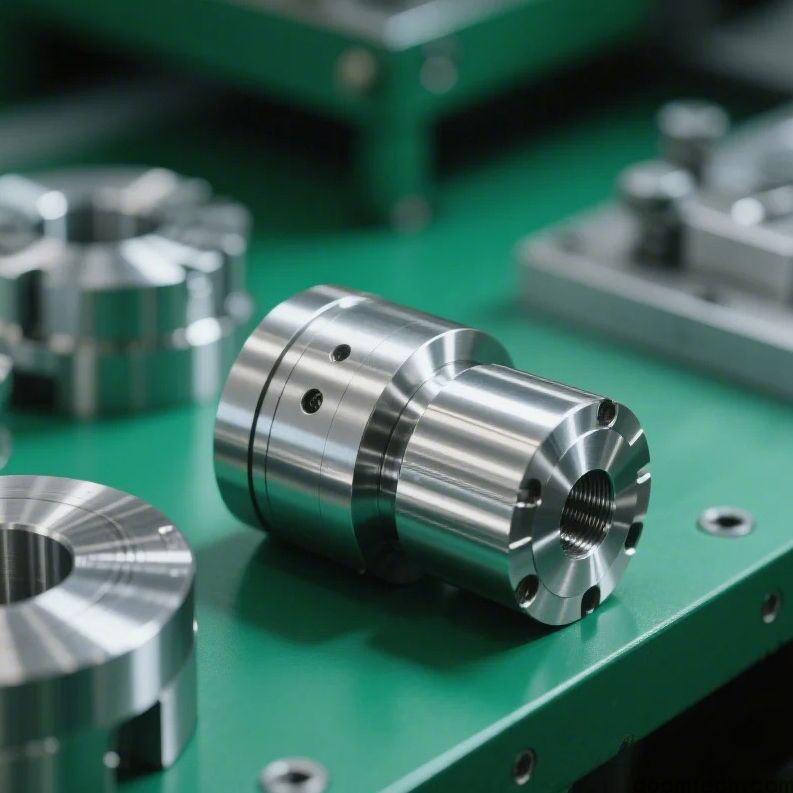

Processing hard materials like titanium, hardened steel, or Inconel requires specialized CNC machining techniques. At AOOM, we employ advanced tooling strategies and rigid machine setups to maintain precision while minimizing tool wear. The key challenges include heat generation, excessive tool pressure, and achieving desired surface finishes.

Critical Techniques for Hard Material CNC Machining

1. Tool selection: We use carbide or CBN tools with specialized coatings (TiAlN, diamond-like carbon) that withstand high temperatures.

2. Optimized cutting parameters: Reduced feed rates with higher spindle speeds prevent work hardening.

3. Rigid fixturing: Our 5-axis machines feature vibration-dampening systems for stability during heavy cuts.

4. Coolant management: Through-tool coolant delivery prevents thermal deformation of workpieces.

AOOM's Hard Material Machining Capabilities

Our facility features:

• 40+ CNC mills/lathes with 15+ dedicated to hard material processing

• In-house tool grinding for custom geometries

• CMM inspection to ensure ±.005mm tolerances

• Post-processing options including heat treatment and precision grinding

Industry Applications

We serve aerospace (turbine components), medical (surgical implants), and automotive (performance drivetrain) industries where hard material machining is critical for product performance and longevity.

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How Much Does Small Batch CNC

How Much Does Small Batch CNC

How to Prevent Deformation in

How to Prevent Deformation in