Your Ultimate Guide to Precision CNC Pinion Gears: Customization, Benefits, and Selection Tips

Hey there, fellow engineers and procurement specialists! 👋 Have you ever been stuck in a project because a standard pinion gear just won't cut it? You know, when the fit isn't perfect, the noise is too high, or it fails under load way sooner than expected? It's frustrating, right? We've all been there. This is where understanding precision CNC pinion gear customization becomes a game-changer. Let's dive into what makes custom pinions so special and how you can make the best choice for your machinery.

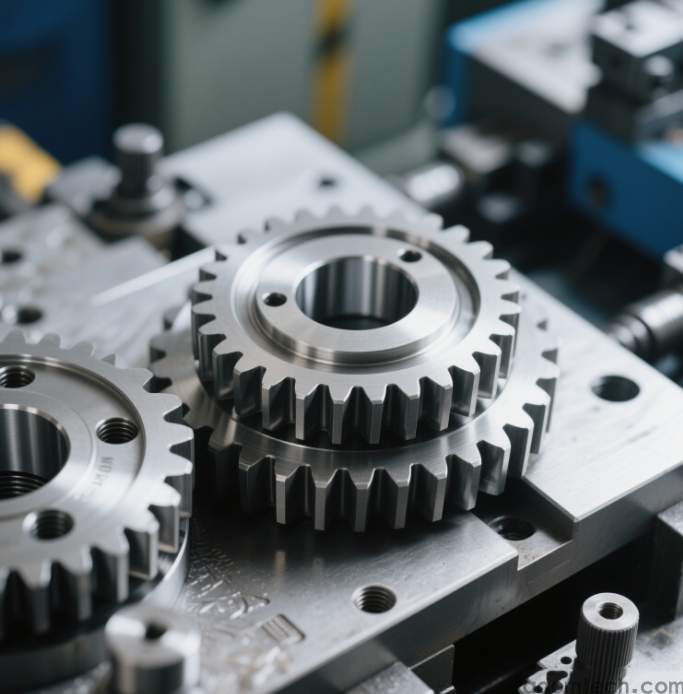

What Exactly is a Custom Precision CNC Pinion Gear?

Think of a standard pinion gear as an off-the-rack suit. It might fit okay, but it's never perfect. A custom precision CNC pinion, on the other hand, is like a bespoke suit tailored exactly to your measurements. In simple terms, it's a small gear that's manufactured using Computer Numerical Control (CNC) machines, but it's made based on your specific requirements—things like exact tooth profile, unique material, special heat treatment, or a non-standard size that you just can't find off the shelf.

Why Should You Consider a Custom Pinion? The Real Benefits

So, why go through the trouble of customizing? The benefits are more tangible than you might think.

✔️ Perfect Fit and Performance: This is the big one. A custom pinion is designed to mesh perfectly with your specific mating gear. This means smoother operation, less vibration, and significantly reduced noise levels. It just works better.

✔️ Unmatched Durability: By choosing the right material and heat treatment process for your application's load and environment, you get a gear that lasts longer. Say goodbye to premature wear and tear!

✔️ Optimized for Your Application: Whether you're dealing with high speeds, heavy loads, or corrosive environments, a custom pinion can be engineered to handle those challenges directly.

I've seen projects turn around completely after switching to a custom solution. The performance leap isn't just minor; it's often dramatic. However, it's worth mentioning that the specific mechanism of how micro-level tooth polishing affects long-term noise reduction is an area that still deserves more research, even though the overall benefits are clear.

How Do You Even Start the Customization Process?

Getting a custom pinion might sound complex, but it's a pretty straightforward conversation with the right manufacturing partner. Here's what you typically need to provide:

👉 Detailed Specifications: This includes the number of teeth, module or pitch, pressure angle, and face width.

👉 Material Choice: Do you need steel, stainless steel, brass, or something like plastic? Think about strength, weight, and corrosion resistance.

👉 Tolerance and Quality Requirements: How precise does it need to be? Defining this upfront avoids surprises.

👉 Application Details: What will this pinion be doing? Sharing the operating context helps the manufacturer suggest the best solutions.

Choosing the Right Partner: It's More Than Just Price

This is where many people get it wrong. Don't just pick the cheapest quote. The capability of your manufacturing partner is everything.

Look for proven experience in gear machining and a portfolio of similar work. Good communication is also key; they should ask a lot of questions to fully understand your needs. A reliable partner will help you navigate the entire process, from material selection to final inspection. Perhaps this suggests that a slightly higher initial investment in a quality supplier pays off tenfold in reduced downtime and headaches.

But let's be real, having all the right specs doesn't always guarantee a perfect outcome on the first try. Sometimes, a small tweak in the design based on real-world feedback from the manufacturer makes all the difference.

My Personal Take on Material Selection

From my experience, the material choice is often the most debated topic. Everyone leans towards hardened steel for strength, which is great for high-load applications. But, and this is a big but, it's not always the best choice. For applications where weight is a concern or where you need some shock absorption, a high-strength aluminum alloy or even a engineered polymer might be a smarter, more efficient choice. It's all about the context of use.

Feeling ready to explore a custom solution for your project? If you have a specific design in mind or just a problem you need to solve, reaching out for a professional opinion is the best next step. Why not discuss your requirements with a technical expert today? They can help you translate your needs into a high-performance, custom CNC pinion gear. 🚀

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How Much Does Small Batch CNC

How Much Does Small Batch CNC

How to Prevent Deformation in

How to Prevent Deformation in