How Much Does Stainless Steel CNC Machining Cost? A Clear Pricing Guide

Feeling stuck because you need a custom stainless steel part, but you have no idea how much it will cost? 🤔 You're not alone. Many buyers and engineers get quotes that seem all over the place. Let's break down the real costs behind stainless steel CNC machining, so your next project doesn't come with a scary price tag.

So, What's the Final Bill? It's Not Just One Number

Asking "how much does it cost?" is like asking how much a car costs. It depends! A basic model is very different from a luxury one. For CNC machining stainless steel, the final price isn't a single number. It's a puzzle made up of a few key pieces: the material you use, the complexity of your part, how many you need, and the extra work needed afterward. We'll look at each of these pieces next.

Material Choice: Not All Steel is the Same 💰

The type of stainless steel you pick is a huge part of the cost. Some are easier to cut and last longer, which can save you money in the long run.

Common Types and Their Impact:

• 304 Stainless Steel: The popular, all-around choice. It's a good balance of cost and performance for many projects.

• 316 Stainless Steel: Better at resisting chemicals and saltwater. This one is often more expensive to buy and can be a bit tougher to machine.

• 303 Stainless Steel: Designed to be easier to cut, which might mean lower machine time costs. But the raw material itself might cost a bit more.

So, while 316 is "better" in some ways, that performance comes with a higher price tag for your project.

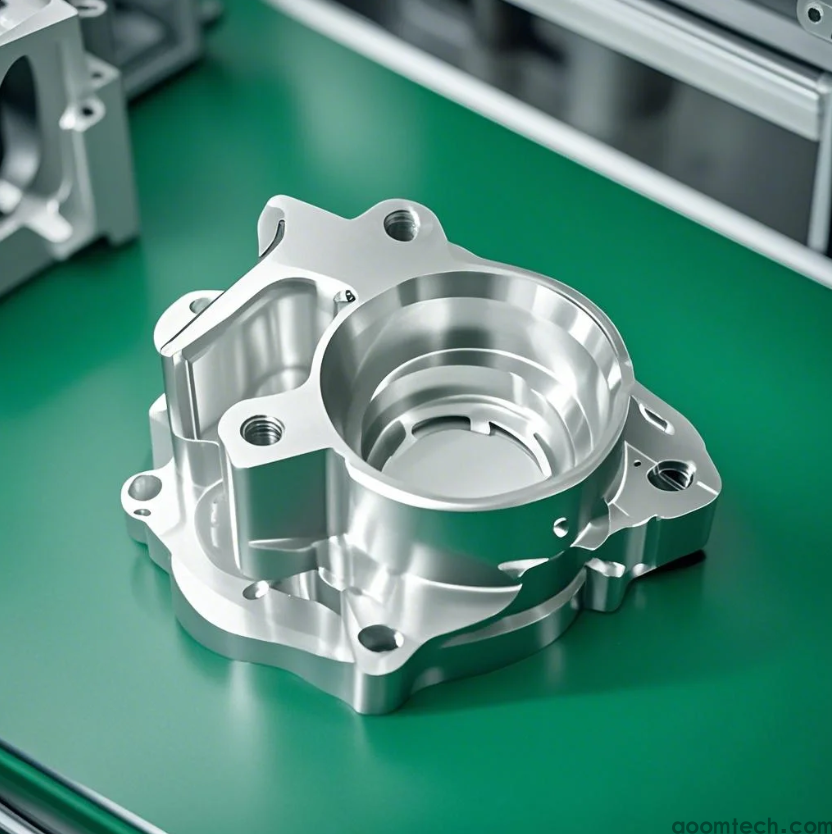

Part Design: Complexity is a Silent Budget Killer

This might be the biggest surprise for people. A simple block is cheap. A part with tiny holes, super tight corners, and complex curves? That's where the cost really starts to climb.

What Makes a Part Expensive to Machine:

• Super Tight Tolerances: Asking for perfection (like within .01mm) means the machine has to work slower and the operator has to check more often.

• Super Smooth Finishes: A mirror-like finish doesn't happen by magic. It needs special tools and extra polishing steps.

• Super Thin Walls or Deep Holes: These are tricky. They require careful handling and special tools to avoid breaking the part or the tool.

Sometimes, a small design change can make a part much easier and cheaper to make, without hurting how it works. It's worth talking about this with your machining partner.

Quantity and Setup: Why One Part Costs More Per Piece

Here's a weird one: the first part you make is always the most expensive. Why? Because of the setup time. The machine needs to be programmed, tools need to be set up, and a first article needs to be checked.

Once that's done, making the second, tenth, or hundredth part is much faster and cheaper per piece. The machine just repeats the process. So, if you're making a lot of the same thing, the cost for each one drops significantly. But if you only need one or two, you're paying mostly for that initial setup work.

Beyond Machining: The "Hidden" Finishing Costs

When the part comes off the machine, it's often not ready to use. It might need a final touch. These extra steps add to your final cost.

Common Extra Steps:

• Deburring: Getting rid of sharp edges and tiny bits of leftover material.

• Passivation: This is a chemical treatment that makes the stainless steel even more resistant to rust. It's almost a must-do for many applications.

• Polishing or Sandblasting: These processes change how the part looks and feels, from a brushed look to a shiny mirror finish.

Each of these is a separate step that needs time, chemicals, or labor, so remember to factor them in.

Getting the Best Price: It's More Than Just Shopping Around

So, how do you make sure you're not overpaying? I've found that the best results don't always come from just picking the cheapest quote. It's about clear communication. Providing a clear 3D model and drawing, talking about what the part is actually for, and being open to small design changes can help a good supplier give you a much more accurate and competitive price. A very low price might sometimes mean they missed something in your complex design.

Still unsure about the cost for your specific part? The best way to get a clear, no-surprise price is to talk directly with an expert. Reach out to our online team now for a fast and personalized quote. We're here to help you figure it out! 👍

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How Much Does Small Batch CNC

How Much Does Small Batch CNC

How to Prevent Deformation in

How to Prevent Deformation in