Precision CNC Aluminum Machining: Process and Benefits for Industrial Applications

Views :

Update time : 2025-04-03

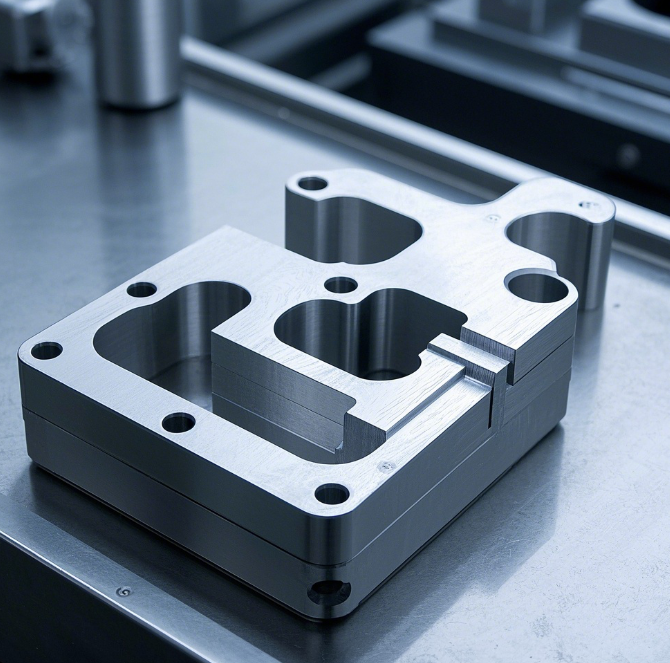

As a leading CNC machining service provider, AOOM specializes in delivering high-precision CNC aluminum machining solutions for industries ranging from aerospace to automotive. Our advanced manufacturing capabilities ensure exceptional dimensional accuracy and surface finishes for critical components.

The CNC Aluminum Machining Process Explained

Our CNC aluminum machining process begins with rigorous material selection, using premium-grade aluminum alloys (6061, 7075, etc.). Through computer-controlled milling, turning, and drilling operations, we achieve tolerances as tight as ±.005mm. The process includes:

- CAD/CAM programming optimization

- High-speed machining with rigid tooling

- In-process quality verification

- Post-machining treatments (anodizing, polishing)

Why Choose AOOM for Your Aluminum Components

AOOM's CNC machining services stand out through:

- 15+ years of aerospace-grade machining experience

- Swiss-type and 5-axis machining centers

- ISO 9001-certified quality management

- Prototype to mass production capabilities

Applications Across Industries

Our precision aluminum parts serve critical functions in:

- Aircraft structural components

- Automotive transmission housings

- Medical device enclosures

- Robotics actuator systems

Related News

Read more >>

CNC Machining Parts Customizat

CNC Machining Parts Customizat

07 .07.2025

As a professional CNC machining service provider, AOOM Technology specializes in delivering high-pre...

Recommendation for CNC Precisi

Recommendation for CNC Precisi

07 .07.2025

When it comes to sourcing high-quality Manufacturers of CNC Precision Parts and Components, business...

CNC Precision Machining Custom

CNC Precision Machining Custom

07 .07.2025

As a leading CNC precision machining service provider, AOOM Technology specializes in manufacturing ...

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F

07 .06.2025

As a leading CNC machining service provider, AOOM Technologies specializes in manufacturing high-pre...