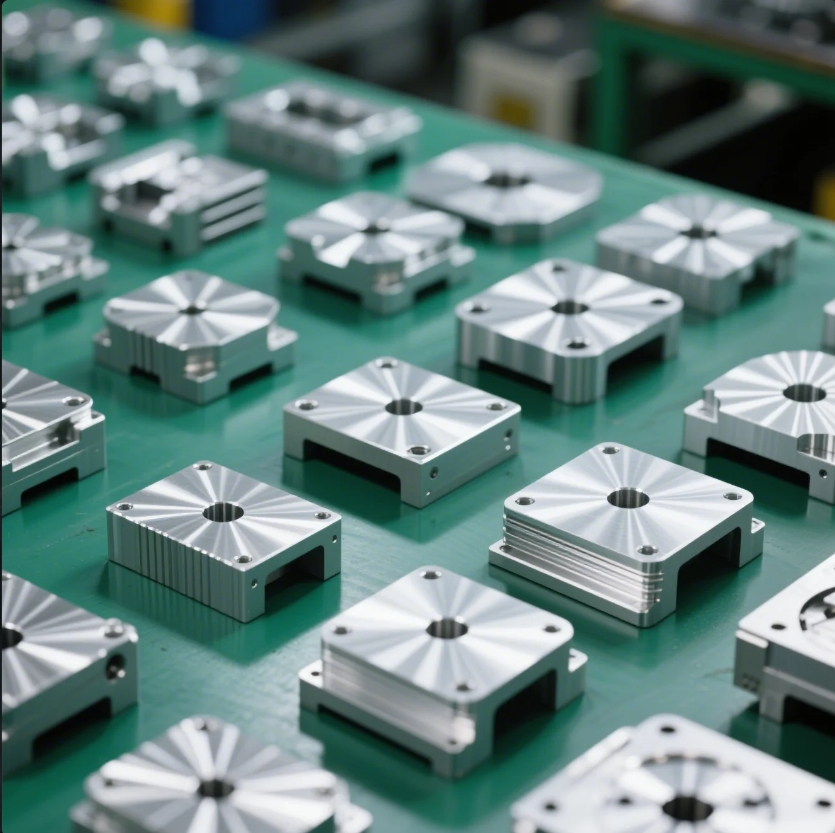

CNC Aluminum Alloy Machining Process

As a professional CNC machining service provider, AOOM Technology specializes in delivering high-precision aluminum alloy components for industries ranging from aerospace to automotive. This article explores the critical aspects of CNC aluminum alloy machining, addressing common challenges and showcasing our technical expertise.

Understanding CNC Aluminum Alloy Machining

Aluminum alloys are widely used in CNC machining due to their excellent strength-to-weight ratio, corrosion resistance, and machinability. The process involves using computer-controlled tools to remove material from aluminum workpieces with micron-level precision. At AOOM, we employ advanced 3/4/5-axis CNC machines capable of producing complex geometries with tight tolerances (±.01mm).

Key Process Considerations

Successful aluminum CNC machining requires attention to several factors:

- Material selection (6061, 7075, 5052 alloys)

- Toolpath optimization to prevent deformation

- Proper cooling techniques to avoid heat buildup

- Surface finishing options (anodizing, polishing, powder coating)

Why Choose AOOM for Your Aluminum Machining Needs?

Our ISO 9001-certified facility combines cutting-edge equipment with decades of machining experience. We offer:

- Prototype to mass production capabilities

- DFM (Design for Manufacturing) analysis

- Comprehensive quality control with CMM inspection

- Competitive lead times (as fast as 5 working days)

For more information about our CNC aluminum machining services, visit our website at www.aoomtech.com or contact our engineering team for a free project evaluation.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F