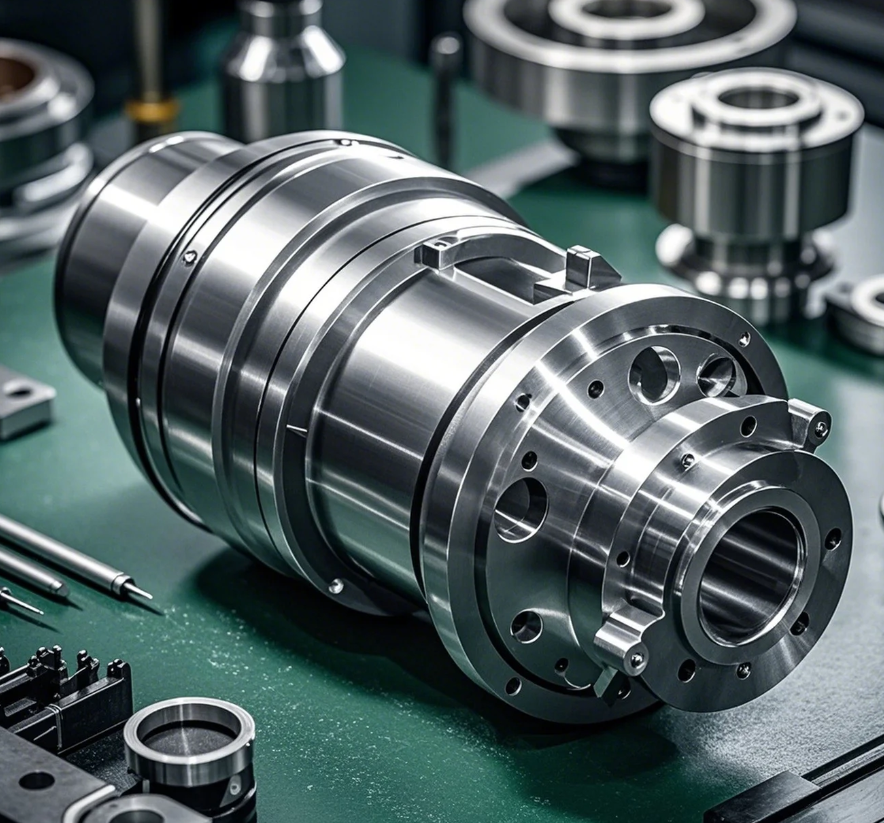

Aluminum Plate CNC Machining

When precision meets durability, aluminum plate CNC machining stands as the premier solution for industries demanding high-strength, lightweight components. As an ISO-certified manufacturer, AOOM Technologies delivers exceptional CNC machining services for aluminum plates across aerospace, automotive, and industrial applications.

Why Choose CNC Machining for Aluminum Plates?

CNC machining offers unparalleled advantages for aluminum plate fabrication:

- ±.005mm dimensional accuracy

- Superior surface finishes (Ra .8μm achievable)

- Complex geometries with tight tolerances

- Repeatable quality for mass production

Our Aluminum CNC Machining Capabilities

AOOM's advanced CNC machining workshops feature:

- 5-axis machining centers for complex contours

- High-speed spindles (up to 20,000 RPM)

- Automated tool changers (60+ tools capacity)

- In-process inspection with CMM

Material Expertise

We machine all aluminum grades including:

- 6061-T6 (most common structural alloy)

- 7075-T6 (aerospace-grade strength)

- 5052 (excellent corrosion resistance)

- 2024 (high fatigue resistance)

Quality Assurance Process

Every aluminum plate CNC component undergoes:

- Material certification verification

- First-article inspection (FAI)

- In-process dimensional checks

- Final CMM validation

- Surface roughness testing

With 15+ years of CNC machining experience, AOOM Technologies has become a trusted partner for precision aluminum components. Our engineers work closely with clients to optimize designs for manufacturability while maintaining strict quality standards. Request your free machining quote today through our online RFQ system at www.aoomtech.com.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F