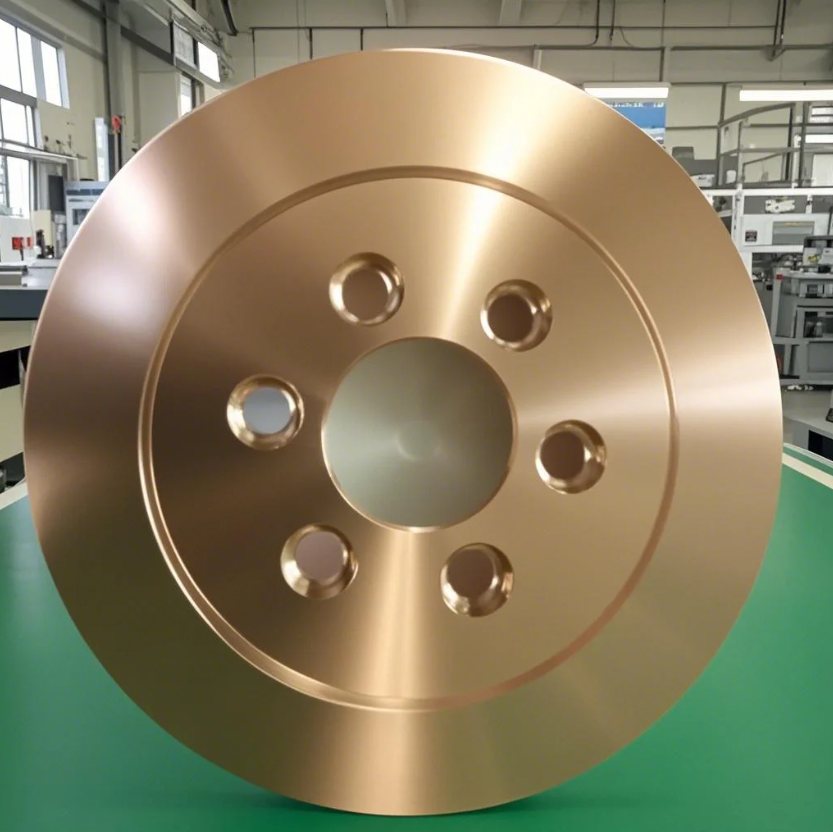

How Does CNC Machine Beryllium Copper?

Beryllium copper is a high-performance alloy widely used in aerospace, electronics, and precision engineering due to its exceptional strength, conductivity, and thermal stability. CNC machining this material requires specialized techniques to ensure dimensional accuracy and surface integrity. As a trusted CNC precision machining manufacturer, AOOM Technologies leverages advanced equipment and process expertise to deliver flawless beryllium copper components.

Key Challenges in CNC Machining Beryllium Copper

1. Tool Wear: The alloy's abrasiveness accelerates tool degradation, demanding carbide or diamond-coated cutters.

2. Heat Management: Excessive heat can alter material properties, requiring optimized cooling strategies.

3. Safety Protocols: Machining generates fine dust particles, necessitating proper ventilation and PPE.

AOOM's Proven Machining Process

Our CNC machining services follow a rigorous workflow for beryllium copper:

- Material Preparation: Pre-machine stress relief annealing to minimize distortion

- Toolpath Optimization: Adaptive toolpaths with reduced stepovers for even tool loading

- Coolant Application: High-pressure coolant to control cutting temperatures

- Post-Processing: Electropolishing or passivation for corrosion resistance

Why Choose AOOM for Beryllium Copper Components?

• ISO 9001-certified quality control

• 5-axis CNC machines with .005mm tolerance

• Material traceability and full-dimension inspection reports

• Prototype to high-volume production capability

Contact AOOM Technologies at www.aoomtech.com for your most demanding beryllium copper machining projects. Our engineering team provides DFM analysis and cost-effective solutions tailored to your specifications.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F