What Are the Advantages of CNC Machining

As a leading CNC machining service provider, AOOM Technology understands the critical advantages that CNC technology brings to modern manufacturing. This article explores the key benefits that make CNC machining the preferred choice for precision parts production across industries.

1. Unmatched Precision and Accuracy

CNC machining delivers exceptional dimensional accuracy, typically within ±.005 inches (±.127mm) or better. Our advanced CNC machines at AOOM Technology maintain tight tolerances consistently, ensuring every part meets exact specifications. This level of precision is crucial for aerospace, medical, and automotive applications where component reliability is paramount.

2. Superior Repeatability and Consistency

Once a CNC program is perfected, it can produce identical parts repeatedly without variation. This manufacturing consistency is invaluable for large production runs where every component must be interchangeable. Our quality control systems at AOOM ensure this consistency across all production batches.

3. Enhanced Production Efficiency

CNC machines operate continuously with minimal supervision, significantly reducing production time compared to manual machining. Automated tool changers and pallet systems in our facilities enable uninterrupted 24/7 operation for time-sensitive projects.

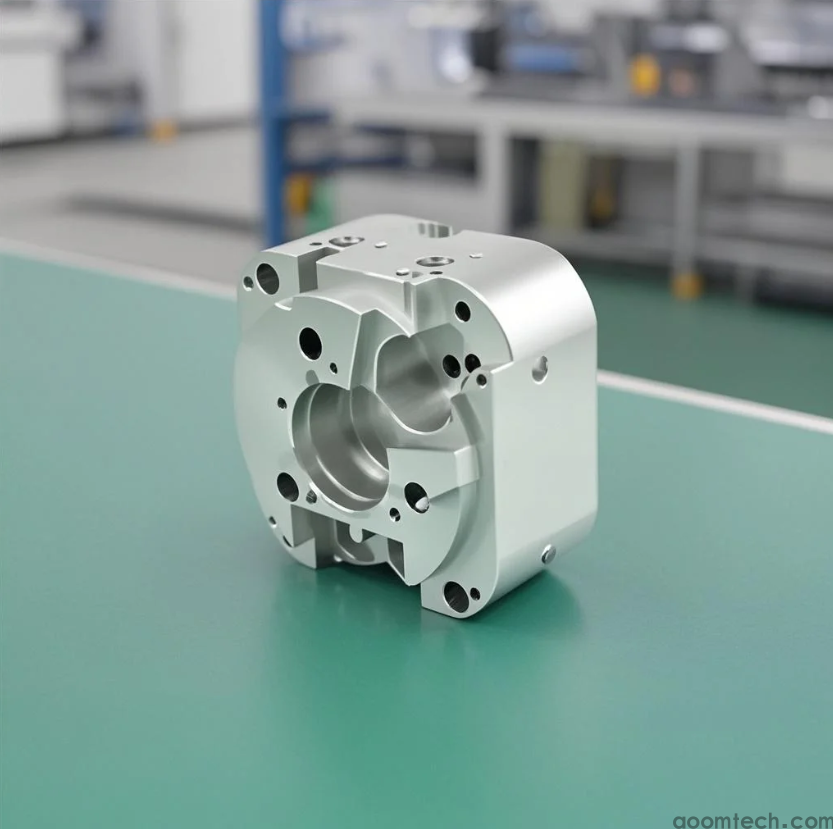

4. Complex Geometries Made Simple

Modern 5-axis CNC machining centers can create intricate shapes that would be impossible or prohibitively expensive with conventional methods. AOOM's multi-axis capabilities allow us to machine complex contours, undercuts, and internal features in a single setup.

5. Material Versatility

From aluminum and stainless steel to engineering plastics and exotic alloys, CNC machines handle an extraordinary range of materials. Our expertise at AOOM includes machining over 50 different material grades to meet diverse industry requirements.

6. Reduced Waste and Cost Efficiency

CNC machining is a subtractive process that optimizes material usage through precise programming. Our nesting software at AOOM maximizes material yield, while automated processes minimize labor costs - delivering cost-effective manufacturing solutions.

7. Rapid Prototyping to Full Production

CNC machining bridges the gap between prototyping and mass production seamlessly. AOOM offers quick-turn prototyping services using the same equipment that handles full production runs, ensuring design continuity and faster time-to-market.

8. Improved Worker Safety

With operators separated from cutting tools and automated safety features, CNC machining significantly reduces workplace hazards compared to manual machining operations.

At AOOM Technology, we combine these inherent CNC advantages with our technical expertise, advanced equipment, and quality management systems to deliver superior machining solutions. Contact us today to discuss how our CNC machining services can benefit your specific application requirements.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F