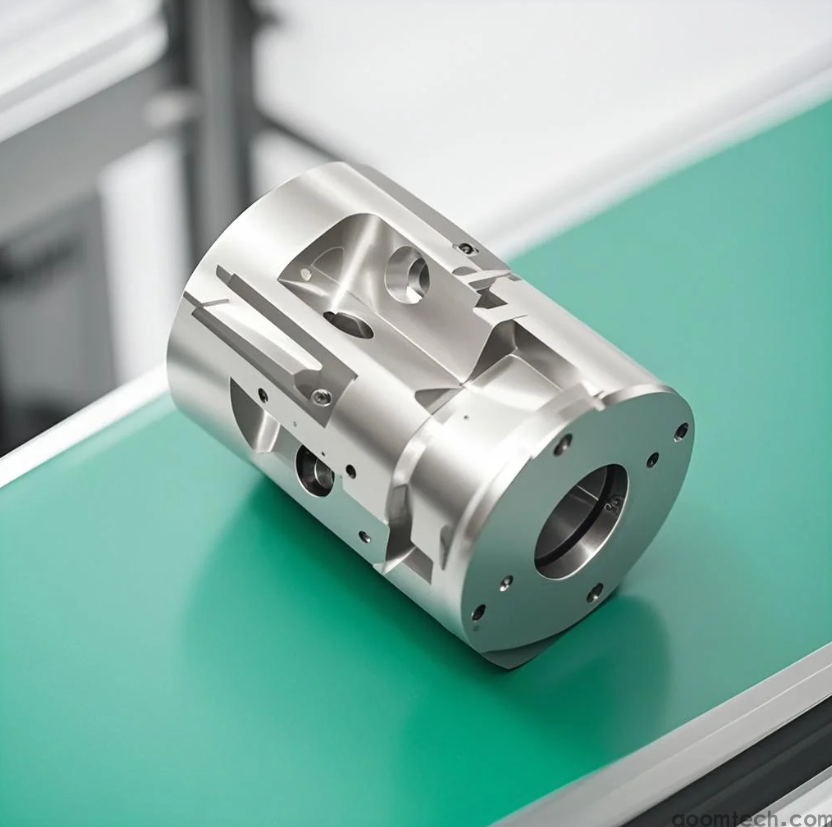

CNC Aluminum Parts Processing Technology

As a leading CNC machining service provider, AOOM Technology specializes in delivering high-precision aluminum parts for various industries. Our advanced CNC aluminum parts processing technology ensures superior quality and dimensional accuracy for your critical components.

Understanding CNC Aluminum Machining Process

The CNC aluminum parts processing technology involves several critical steps: material selection, CAD/CAM programming, precision machining, quality inspection, and surface treatment. At AOOM, we employ state-of-the-art 5-axis CNC machines capable of handling complex geometries with tight tolerances up to ±.005mm.

Key Advantages of Our CNC Aluminum Processing

1. Material Expertise: We work with all aluminum grades including 6061, 7075, and 2024

2. Advanced Equipment: High-speed CNC mills with automatic tool changers

3. Quality Assurance: ISO 9001 certified processes with CMM inspection

4. Surface Finishes: Anodizing, powder coating, sandblasting, and more

Applications Across Industries

Our CNC aluminum machining services support:

- Aerospace components

- Automotive parts

- Medical equipment

- Electronics enclosures

- Robotics and automation systems

Why Choose AOOM for Your Aluminum CNC Needs?

With 15+ years of experience in precision machining, AOOM Technology offers:

- Fast turnaround (as quick as 3 days)

- Competitive pricing for both prototypes and mass production

- DFM (Design for Manufacturing) consultation

- Strict confidentiality for proprietary designs

Visit our website at www.aoomtech.com to request a free quote or discuss your project requirements with our engineering team today.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F