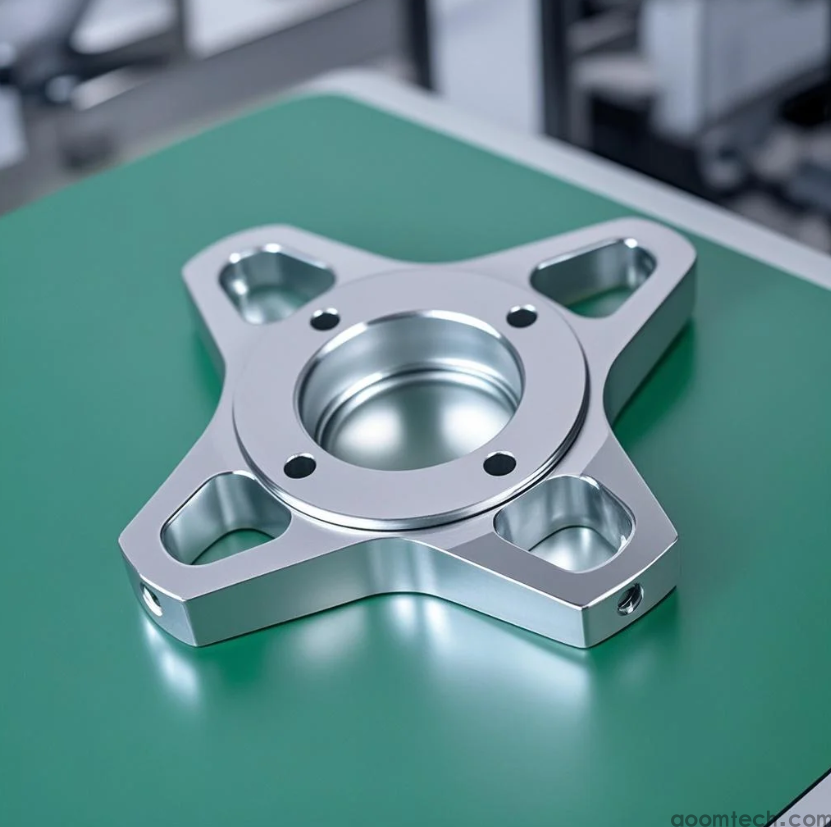

CNC Mass Aluminum Machining Process

As a leading CNC machining service provider, AOOM Technology specializes in high-volume aluminum processing with precision and efficiency. This article will explore the critical aspects of CNC Mass Aluminum Machining Process (CNC batch aluminum processing technology) that meets industrial demands.

Understanding CNC Batch Aluminum Processing

Batch processing of aluminum components requires specialized CNC machining techniques to maintain consistency across large production runs. Our ISO-certified facility at AOOM employs advanced 5-axis CNC machines capable of handling aluminum alloys from 6061 to 7075 with micron-level precision.

Key Process Stages

The standard workflow includes:

1. Material Selection: Choosing the optimal aluminum grade for mechanical properties

2. Precision Programming: CAD/CAM optimization for batch production

3. Machining: Multi-stage milling, drilling, and tapping operations

4. Quality Control: Automated CMM inspection for every 10th part

Advantages of Our Batch Processing

AOOM's proprietary toolpath algorithms reduce cycle times by 18-22% compared to conventional methods. Our dust extraction systems maintain machining accuracy even during 24/7 production runs, achieving surface finishes up to Ra .4μm.

Industry Applications

This technology serves:

- Aerospace structural components

- Automotive heat sinks

- Electronics enclosures

- Medical device parts

With 15+ years of aluminum machining experience, AOOM guarantees ±.01mm tolerances and delivers batches from 100 to 100,000 units. Contact our engineering team at www.aoomtech.com for DFM analysis and project quotes.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F