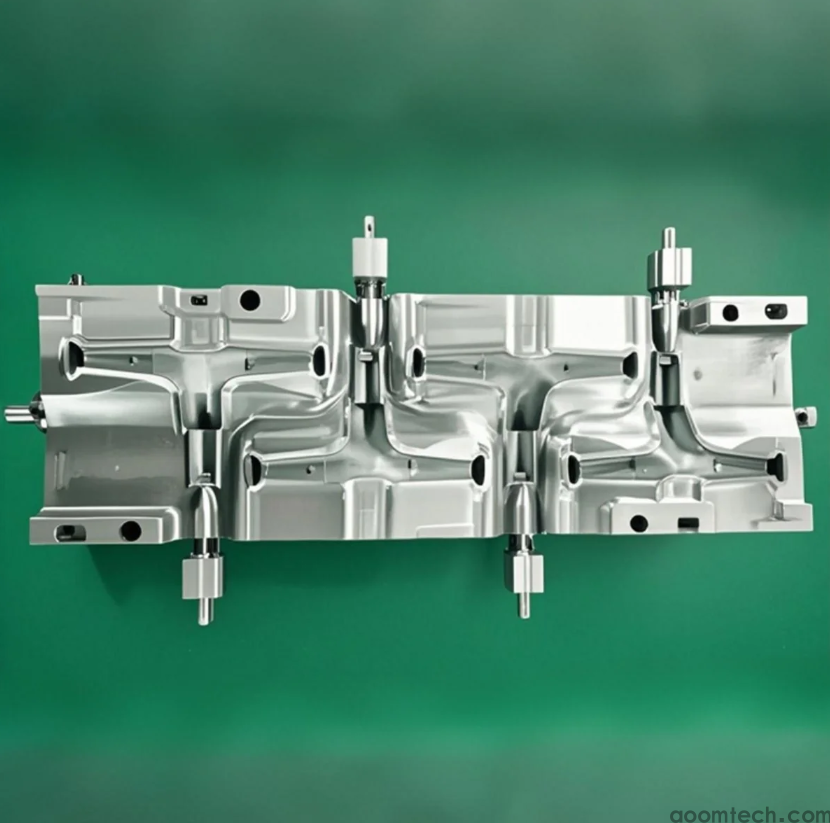

CNC Mold Precision Machining Process

As a leading CNC machining service provider, AOOM Technology specializes in delivering high-precision mold manufacturing solutions for industries requiring micron-level accuracy. Our CNC mold precision machining process combines advanced equipment with decades of technical expertise to produce durable, complex molds with exceptional surface finishes.

The Critical Stages of CNC Mold Machining

1. Design Analysis: Our engineers use CAD/CAM software to optimize mold designs for manufacturability and performance

2. Material Selection: We recommend premium tool steels (P20, H13) or aluminum alloys based on application requirements

3. Precision Machining: 5-axis CNC mills achieve ±.005mm tolerances with mirror finishes (Ra .2μm achievable)

4. Quality Verification: CMM inspection and surface roughness testing ensure every mold meets specifications

Why Choose AOOM for Your Mold Manufacturing?

• 40+ CNC machines including high-speed milling centers (20,000 RPM+)

• ISO 9001-certified quality management system

• 15-year experience in complex mold making for automotive, medical, and electronics industries

• Complete post-processing capabilities (EDM, polishing, heat treatment)

Technical Advantages of Our Process

Our CNC mold precision machining delivers:

• Extended mold lifespan through proper grain direction control

• Faster cycle times with optimized cooling channel machining

• Reduced secondary operations via high-precision contouring

Visit aoomtech.com to request a free DFM analysis for your next mold project. Our engineering team provides technical support throughout your product development cycle.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F