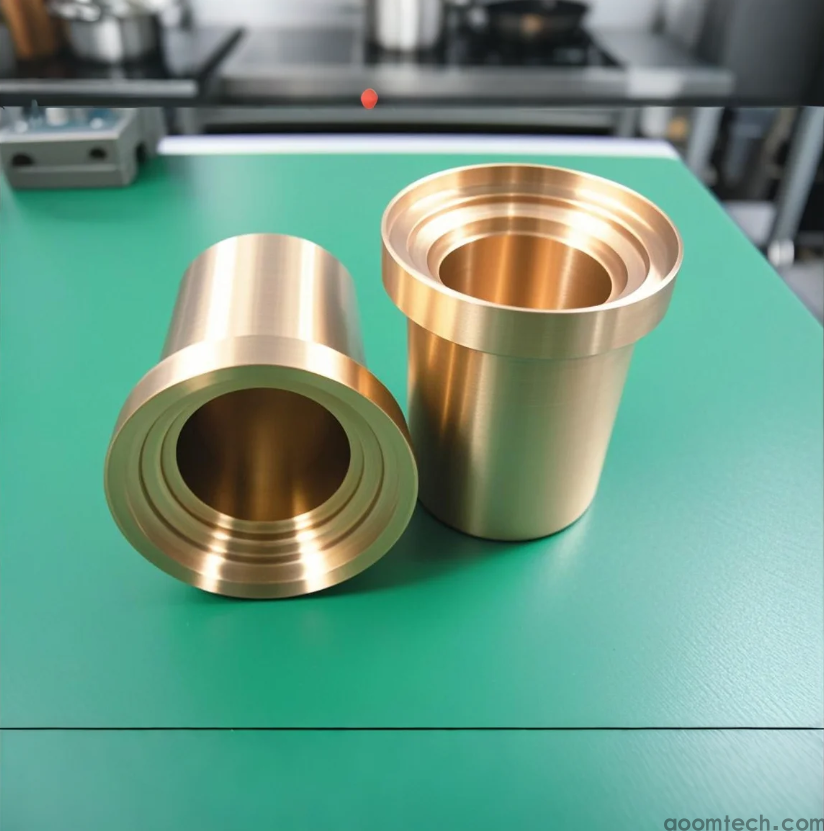

CNC Machining Pure Copper Crafts

In the realm of precision manufacturing, CNC machining pure copper crafts represents a specialized niche that demands exceptional technical expertise. At AOOM, we combine advanced CNC technology with artisan-level craftsmanship to deliver flawless copper components for industrial, decorative, and functional applications.

Why Choose CNC for Pure Copper Craftsmanship?

Pure copper's unique properties – including high thermal/electrical conductivity and malleability – require tailored machining approaches. Our CNC machining processes address copper's tendency to gall and deform through:

- Precision-controlled spindle speeds (optimized between 800-150 RPM)

- Specialized tool geometries with polished flutes

- Micro-lubrication systems preventing material adhesion

- Rigid fixturing solutions minimizing vibration

Technical Capabilities at AOOM

Our 5-axis CNC centers achieve ±.01mm tolerances on complex copper geometries, supporting:

- Intricate artistic engravings

- Precision electrical contacts

- Antimicrobial architectural fixtures

- High-purity laboratory components

Quality Assurance Protocol

Every pure copper craft undergoes stringent verification including:

- 3D scanning for dimensional accuracy

- Surface roughness testing (Ra ≤ .4μm achievable)

- Eddy current conductivity verification

- Visual inspection under 10x magnification

Discover how AOOM's CNC expertise transforms raw copper into precision masterpieces. Contact our engineering team for project-specific solutions.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F