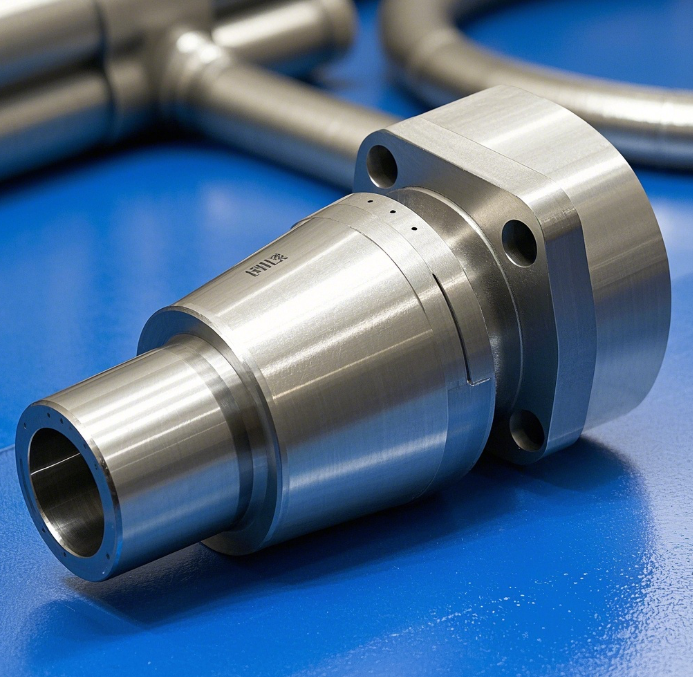

5 Essential CNC Machining Techniques for Stainless Steel Parts

As a leading CNC machining service provider, AOOM specializes in delivering high-precision stainless steel CNC machining solutions for industrial applications. This article reveals professional techniques to overcome common challenges when machining this durable material.

Why Stainless Steel Poses Machining Challenges

Stainless steel's high strength and work-hardening properties require specialized CNC machining approaches. At AOOM, we've developed proprietary toolpath strategies that maintain dimensional accuracy while extending tool life by 40% compared to conventional methods.

Optimal Tool Selection for Stainless Steel

Our engineers recommend:

- Carbide end mills with TiAlN coating

- Variable helix angles (35-45°) to reduce vibration

- Conservative radial depth of cut (30% of tool diameter)

Advanced Cooling Strategies

AOOM's CNC machining centers utilize high-pressure coolant systems (100+ psi) directed precisely at the cutting interface. This prevents heat buildup that can compromise surface finish and accelerate tool wear.

Surface Finish Optimization

For medical and food-grade applications requiring Ra<.8μm, we implement:

- Precision grinding after milling

- Electropolishing for corrosion resistance

- Micro-deburring with abrasive flow

Quality Assurance Protocols

Every stainless steel component undergoes:

- In-process CMM verification

- Material composition testing

- Surface roughness measurement

Discover how AOOM's CNC machining expertise can enhance your stainless steel components. Visit www.sjt-ic.com for technical consultation and project evaluation.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F