5 Advanced CNC Machining Techniques for Aluminum Plates

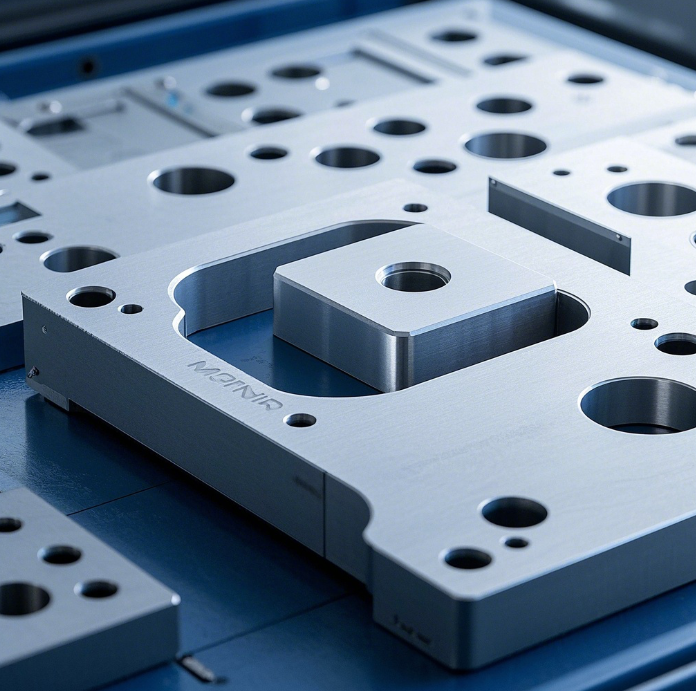

Aluminum plates are widely used in industries like aerospace, automotive, and electronics due to their lightweight and durability. CNC machining offers precision and efficiency in processing aluminum plates. This article explores key methods to optimize your production.

1. Choosing the Right Cutting Tools

For aluminum plates, carbide or diamond-coated tools are recommended. These materials reduce heat buildup and extend tool life. High-speed steel (HSS) tools can also be used but may require more frequent replacements.

2. Optimizing Feed Rates and Speeds

Aluminum is softer than steel but can gum up tools if not machined correctly. A feed rate of .1-.3 mm/tooth and spindle speeds of 10,000-15,000 RPM are ideal for most CNC aluminum machining applications.

3. Effective Cooling Strategies

Use flood coolant or mist systems to prevent overheating and improve surface finish. Proper cooling also helps in chip evacuation, reducing the risk of tool clogging.

4. Precision Fixturing for Thin Plates

Thin aluminum plates can warp during machining. Vacuum fixtures or custom clamps ensure stability and maintain dimensional accuracy throughout the CNC machining process.

5. Post-Machining Treatments

Anodizing or powder coating can enhance corrosion resistance and aesthetics. Deburring is also crucial to achieve smooth edges and meet strict industry standards.

At AOOM, we specialize in high-precision CNC machining of aluminum plates. Our advanced equipment and skilled technicians guarantee quality results for your most demanding projects. Visit our website to learn more about our capabilities.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F