CNC Mold Machining Factory Recommendation

When sourcing precision CNC mold machining services, selecting the right factory is critical for product quality and project success. As a trusted CNC machining specialist, AOOM Technology provides expert guidance on evaluating mold manufacturing partners.

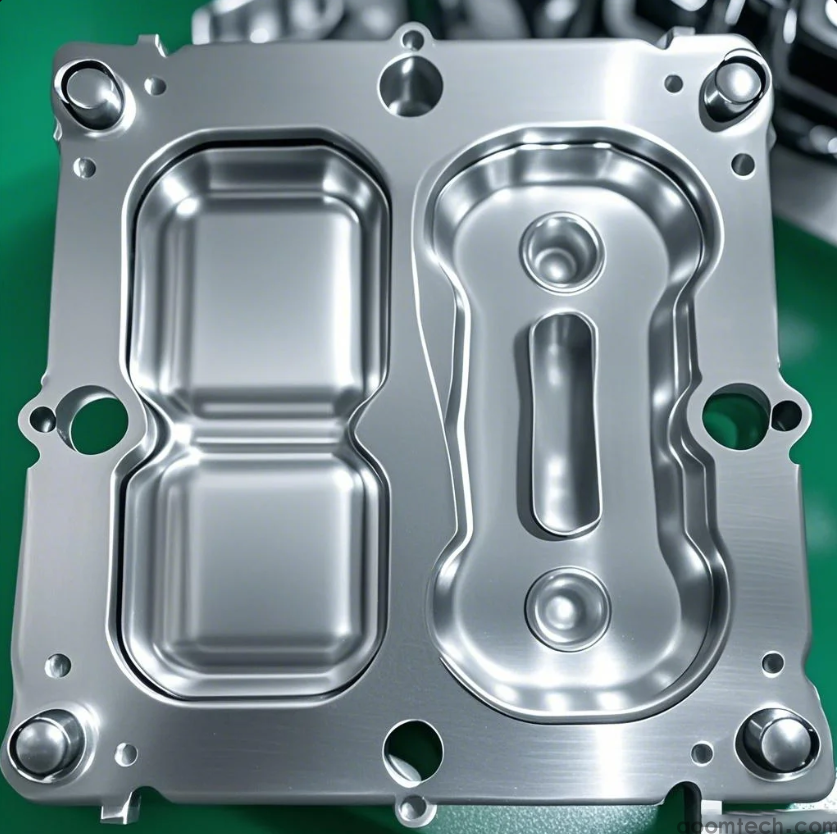

Key Selection Criteria for CNC Mold Factories

1. Precision Capabilities: Verify micron-level tolerance achievement (typically ±.01mm for mold work)

2. Material Expertise: Check experience with mold steels (P20, H13), aluminum alloys, and copper electrodes

3. Surface Finish Mastery: Confirm polishing (Ra .025μm) and texture replication abilities

4. Tooling Inventory: Ensure availability of high-performance carbide end mills and EDM electrodes

AOOM's Mold Machining Advantages

Our CNC mold machining services feature:

• 50+ Swiss-made CNC milling/turning centers with 5-axis capability

• Class 10,000 clean room for optical-grade surface finishing

• Moldflow simulation integration for warp-free results

• ISO 9001-certified quality management system

Technical Comparison: Standard vs. Precision Mold Making

Parameter Standard Precision (AOOM)

Tolerance ±.05mm ±.005mm

Surface Finish Ra .8μm Ra .1μm

Lead Time 4-6 weeks 2-3 weeks

Industry-Specific Solutions

We specialize in:

• Injection molds for medical devices (ISO 13485 compliant)

• Die-casting molds for automotive components

• Blow molds for PET packaging

• Progressive dies for connector manufacturing

Contact AOOM at www.aoomtech.com for DFM analysis and project consultation with our mold engineering team.

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How Much Does Small Batch CNC

How Much Does Small Batch CNC

How to Prevent Deformation in

How to Prevent Deformation in