CNC Mold Processing and Mold Repair Precautions

As a leading CNC machining service provider, AOOM Technology specializes in precision mold manufacturing and repair services. This article will address the critical considerations in CNC mold processing and mold repair operations.

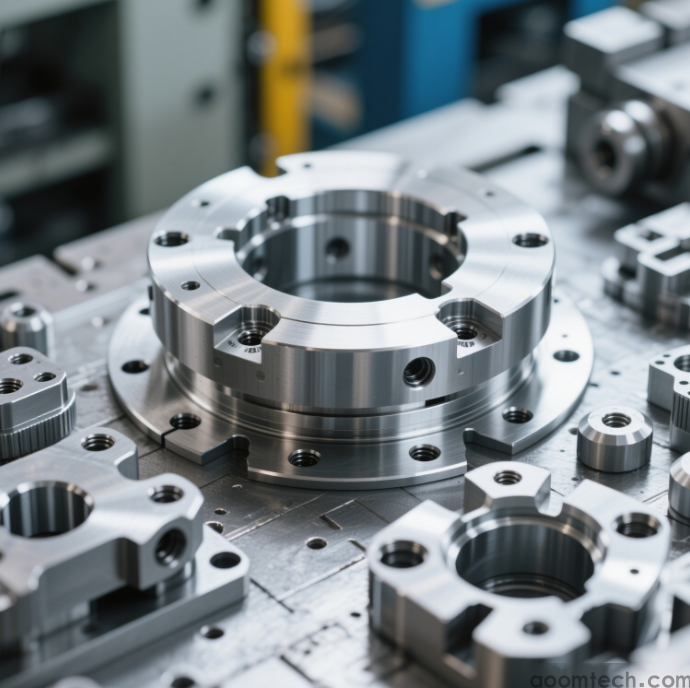

Understanding CNC Mold Processing

CNC mold processing involves using computer-controlled machines to create precise molds for various manufacturing applications. At AOOM, we utilize advanced 5-axis CNC machines capable of achieving tolerances within ±.01mm, ensuring high-quality mold production for industries ranging from automotive to consumer electronics.

Key Precautions in Mold Repair

When performing mold repair using CNC technology, several critical factors must be considered:

Material Analysis: Always verify the mold material properties before machining to select appropriate tools and parameters.

Precision Measurement: Use high-precision measuring instruments to identify wear patterns and deformation areas.

Process Optimization: Adjust cutting parameters based on the repair requirements to maintain structural integrity.

Surface Treatment: Consider post-processing treatments like polishing or coating after repair operations.

AOOM's Technical Advantages in Mold Processing

Our company stands out in the CNC machining industry through:

15+ years of mold manufacturing experience

ISO 9001-certified quality control system

Advanced CAD/CAM software integration

Comprehensive testing and inspection equipment

Common Mold Repair Scenarios

We regularly handle various mold repair cases including:

Wear compensation on critical surfaces

Crack repair and reinforcement

Dimensional accuracy restoration

Surface finish improvement

For professional CNC mold processing and repair services, visit our website at www.aoomtech.com to learn how our expertise can optimize your mold maintenance and production processes.

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How Much Does Small Batch CNC

How Much Does Small Batch CNC

How to Prevent Deformation in

How to Prevent Deformation in