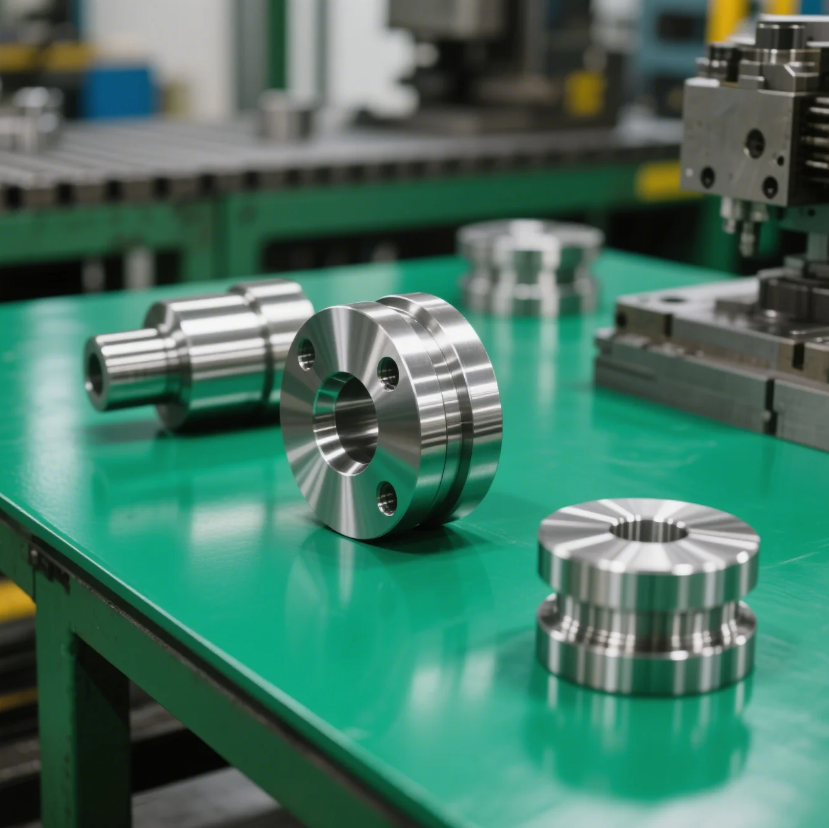

Stainless Steel CNC Machining Considerations

Why Stainless Steel CNC Machining Requires Special Attention?

Stainless steel is widely used in aerospace, medical, and automotive industries due to its corrosion resistance and durability. However, its high hardness and work-hardening properties pose challenges for CNC machining. Understanding these nuances ensures precision, tool longevity, and cost efficiency.

Key Considerations for Stainless Steel CNC Machining

1. Material Selection: Grades like 304, 316, or 17-4PH have varying machinability. AOOM’s engineers analyze your project needs to recommend the optimal grade.

2. Tooling Strategy: Carbide tools with sharp edges and specialized coatings (e.g., TiAlN) reduce heat buildup and wear. Coolant application is critical to prevent thermal deformation.

3. Speed & Feed Rates: Lower RPMs and higher feed rates mitigate work hardening. Our CNC precision machining protocols adjust parameters dynamically for complex geometries.

AOOM’s Expertise in Stainless Steel CNC Solutions

With 12+ years of experience, AOOM (aoomtech.com) delivers:

- Advanced Equipment: 5-axis CNC mills and Swiss-type lathes for tight tolerances (±.005mm).

- Quality Assurance: ISO 9001-certified inspections with CMM and surface roughness testers.

- Cost Optimization: Nesting software minimizes material waste for large batches.

Common Pitfalls and How to Avoid Them

Avoid tool chatter by ensuring rigid setups. For medical implants, electropolishing post-machining enhances biocompatibility. Partner with AOOM to navigate these challenges seamlessly.

Conclusion

Stainless steel CNC machining demands technical mastery. AOOM combines material science expertise with cutting-edge technology to deliver flawless components. Contact us for a DFM analysis today.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F