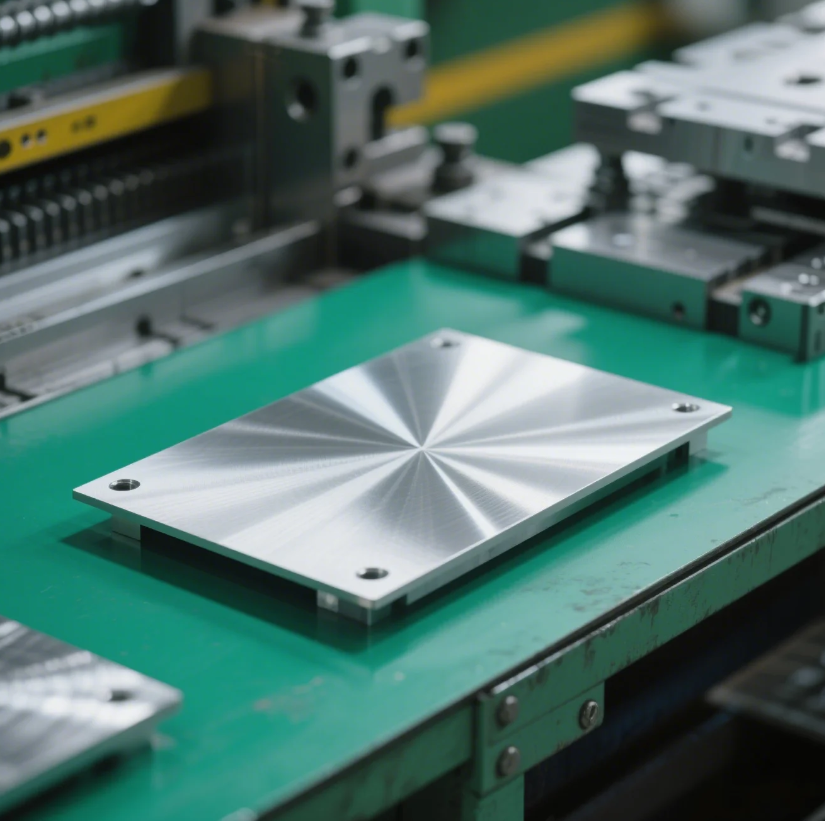

CNC Machining Process for Thin Plates

As a professional CNC machining service provider, AOOM Technology specializes in CNC Machining Process for Thin Plates for industries requiring high-precision thin metal components. This article explores the technical nuances, applications, and advantages of our thin-sheet CNC machining solutions.

What is CNC Thin-Sheet Machining?

CNC Machining Process for Thin Plates refers to the computer-controlled subtractive manufacturing process for metal sheets typically under 3mm thickness. Our ISO 9001-certified facility utilizes advanced 5-axis CNC machines with vacuum clamping systems to ensure dimensional stability during high-speed milling, drilling, and engraving operations.

Key Technical Challenges and Solutions

Thin-sheet machining presents unique challenges that AOOM addresses through proprietary techniques:

- Material Distortion Control: Our temperature-regulated machining environment and optimized tool paths minimize thermal deformation

- Surface Finish: Diamond-cut end mills achieve Ra .2μm surface roughness for critical applications

- Micro-Feature Accuracy: .01mm positional tolerance maintained through real-time laser measurement

Material Capabilities

We process diverse materials for CNC Machining Process for Thin Plates including:

- Aluminum alloys (5052, 6061, 7075)

- Stainless steel (304, 316L)

- Brass and copper alloys

- Titanium (Grade 2/5)

Industry Applications

Our thin-sheet CNC services support:

- Electronics enclosures and heat sinks

- Medical device components

- Aerospace shims and brackets

- Automotive sensor mounts

Why Choose AOOM Technology?

With 15+ years of CNC Machining Process for Thin Plates experience, we offer:

- DFM analysis with free technical consultation

- Prototype to mass production capability

- 100% on-time delivery record

- Material traceability documentation

English Title: CNC Thin-Sheet Machining Process

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F