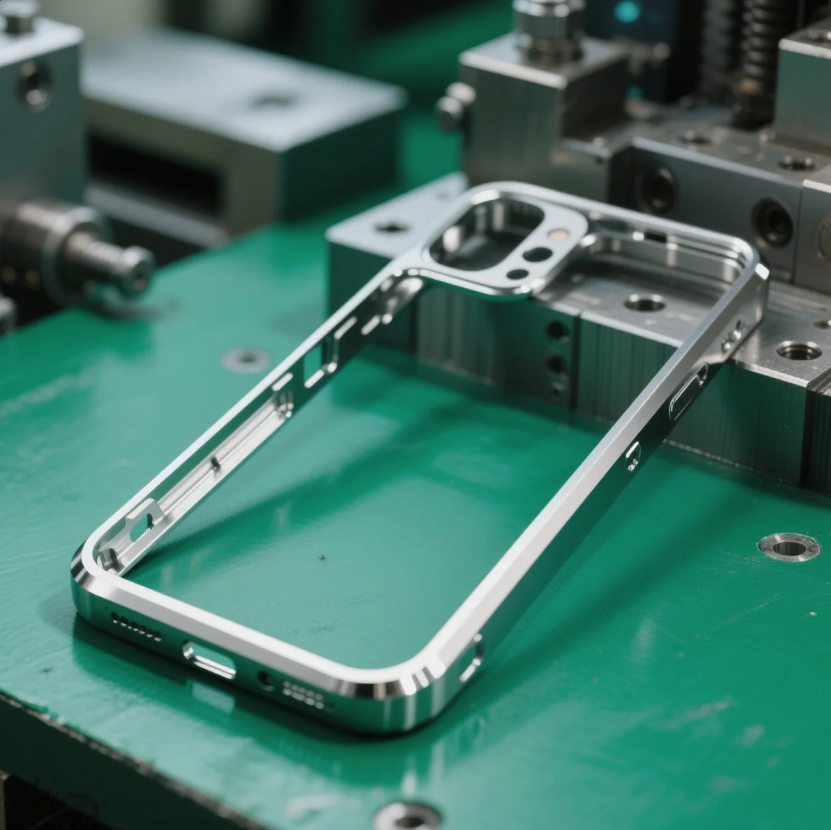

Mobile Phone Bezel CNC Machining Process

As a professional CNC machining service provider, AOOM Technology specializes in delivering high-precision mobile phone bezel CNC machining solutions for industries requiring tight tolerances and superior surface finishes. This article explores the critical aspects of this process, addressing common challenges and showcasing our technical expertise.

Understanding Mobile Phone Bezel CNC Machining

The CNC machining process for mobile phone bezels involves subtractive manufacturing of metal (typically aluminum alloys or stainless steel) to create the thin, complex frames that house modern smartphone displays. Our 5-axis CNC mills achieve ±.01mm precision, ensuring perfect fitment with other components.

Key Technical Considerations

1. Material Selection: We recommend 600-series aluminum for its optimal strength-to-weight ratio and anodization compatibility

2. Surface Treatment: AOOM offers secondary processes including sandblasting, anodizing (up to MIL-A-8625 standards), and PVD coating

3. Structural Integrity: Our toolpath programming maintains minimum wall thickness of .3mm without deformation

Why Choose AOOM for Your Bezel Manufacturing?

With 12 years of CNC machining experience in consumer electronics, we provide:

- Dedicated project engineers for DFM analysis

- ISO 9001-certified quality control

- 15-day standard lead time with 98% on-time delivery

- Full documentation including material certifications and inspection reports

Contact our technical team at AOOM Technology to discuss your specific bezel requirements and receive a free DFM analysis within 24 hours.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F