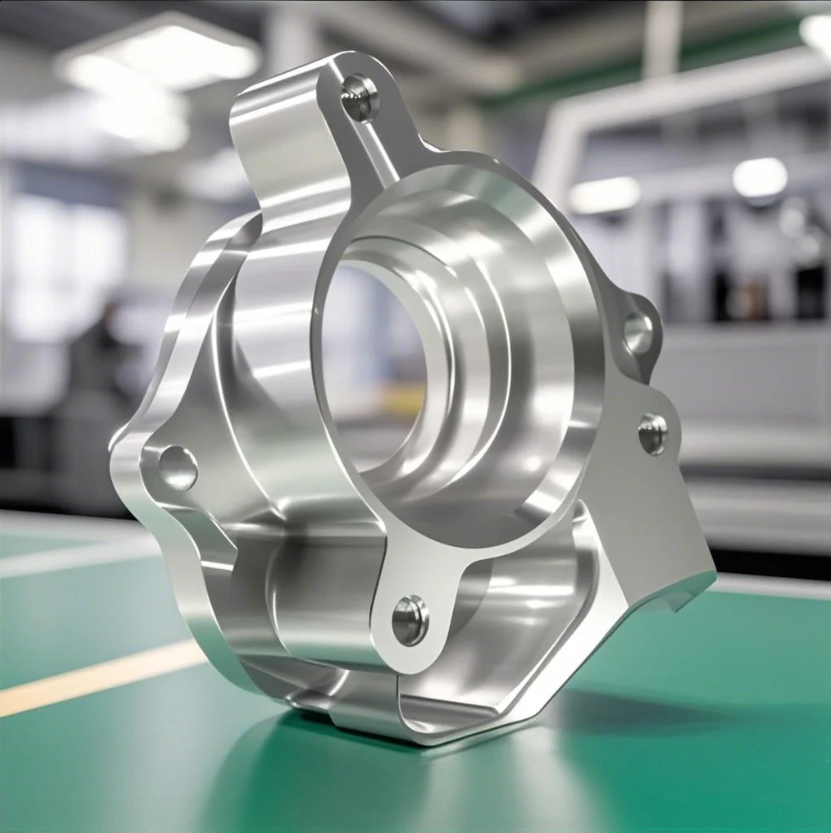

CNC Machining Automotive Parts

In the automotive industry, precision and reliability are non-negotiable. CNC machining automotive parts has become the gold standard for producing high-performance components that meet stringent quality requirements. At AOOM, we specialize in delivering CNC-machined auto parts with unmatched accuracy and durability.

Why Choose CNC Machining for Automotive Components?

Modern vehicles demand parts with tight tolerances, complex geometries, and exceptional material properties. CNC automotive machining offers:

- ±.005mm precision for critical components

- Superior surface finishes (Ra .4μm achievable)

- Material versatility (aluminum alloys, steel, titanium, plastics)

- Repeatable quality for mass production

Our Automotive CNC Machining Capabilities

AOOM's 5-axis CNC centers and Swiss-type lathes produce:

- Engine components (valve seats, pistons, cylinder heads)

- Transmission parts (gears, shafts, housings)

- Suspension elements (control arms, knuckles)

- Brake system components

Quality Assurance for Automotive Applications

We implement IATF 16949-compliant processes including:

- 100% dimensional inspection with CMM

- Material traceability documentation

- Surface hardness testing

- PPAP documentation support

Trust AOOM for your CNC machining automotive parts needs. Our engineers work closely with automotive clients to optimize designs for manufacturability while meeting performance specifications. Contact us at www.aoomtech.com for project consultation.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F