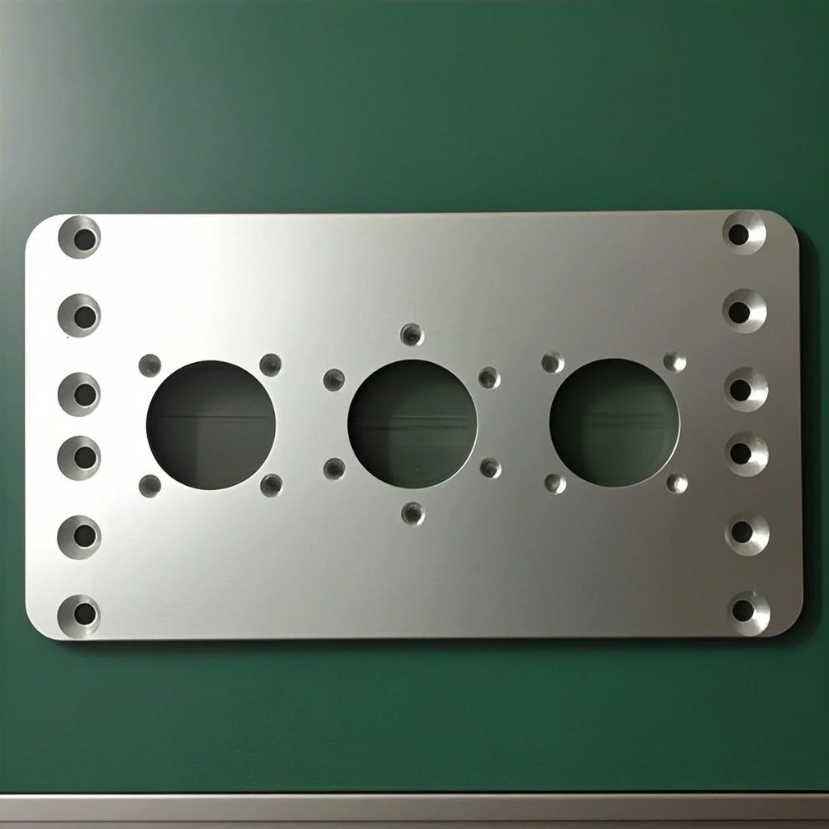

Aluminum Plate CNC Machining: Cost Factors and Precision Solutions

When sourcing aluminum plate CNC machining services, understanding pricing variables is critical for procurement managers and engineers. As a professional CNC machining service provider, AOOM Technology delivers transparent cost structures while maintaining ISO-certified quality standards.

Key Factors Affecting Aluminum CNC Machining Costs

1. Material Grade: 6061 vs. 7075 aluminum alloys differ significantly in machinability and raw material costs.

2. Part Complexity: Multi-axis machining requirements increase programming and cycle times.

3. Surface Finish: Additional processes like anodizing or powder coating add post-processing costs.

4. Order Volume: Bulk orders typically benefit from economies of scale.

AOOM's Competitive Advantages in Aluminum Machining

Our CNC machining facility features:

- 5-axis milling centers for complex geometries

- ±.005mm tolerance capabilities

- In-house quality inspection lab

- DFM (Design for Manufacturing) advisory services

Optimizing Your Project Budget

To achieve cost-efficient aluminum plate CNC machining:

1. Consolidate multiple parts into single setups

2. Standardize tolerances where possible

3. Consider prototype batches before full production

4. Leverage our material sourcing network

Request a customized quote through our website aoomtech.com, including your CAD files and specifications for accurate pricing. Our engineering team provides free design optimization suggestions to reduce costs without compromising functionality.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F