Lamp CNC Machining: Precision Manufacturing for Lighting Components

As a professional CNC machining service provider, AOOM Technologies specializes in lamp CNC machining solutions for various lighting applications. This article explores the technical aspects, material selection, and quality control processes that make us the ideal partner for your lighting component manufacturing needs.

Why Choose CNC Machining for Lamp Components?

CNC machining offers unparalleled precision for lighting fixtures that require complex geometries and tight tolerances. Our 5-axis CNC machines can produce intricate lamp components with smooth finishes, perfect for both functional and aesthetic requirements in modern lighting designs.

Materials for Lamp CNC Machining

We work with various materials suitable for lighting applications:

- Aluminum alloys (lightweight and excellent heat dissipation)

- Brass (for decorative and conductive components)

- Stainless steel (for durable structural parts)

- Engineering plastics (for insulation and diffuser elements)

Our Lamp CNC Machining Capabilities

AOOM Technologies provides complete CNC machining services for lighting products:

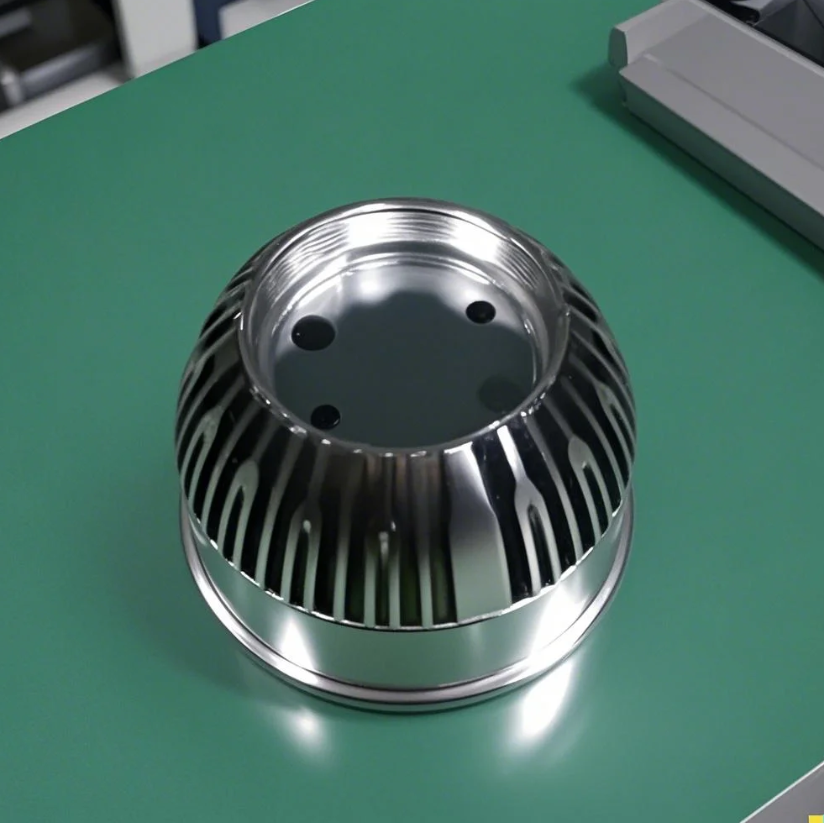

- Precision machining of lamp housings and heat sinks

- Complex reflector and lens component manufacturing

- Threaded connections and mounting solutions

- Surface finishing (anodizing, polishing, powder coating)

Quality Assurance in Lighting Component Production

Every lamp component undergoes rigorous inspection using CMM equipment and optical measurement tools to ensure:

- Dimensional accuracy within ±.01mm

- Proper light reflection/refraction characteristics

- Consistent thermal performance

- Perfect assembly compatibility

For your custom lamp CNC machining requirements, contact AOOM Technologies at www.aoomtech.com to discuss your project specifications and receive a competitive quote.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F