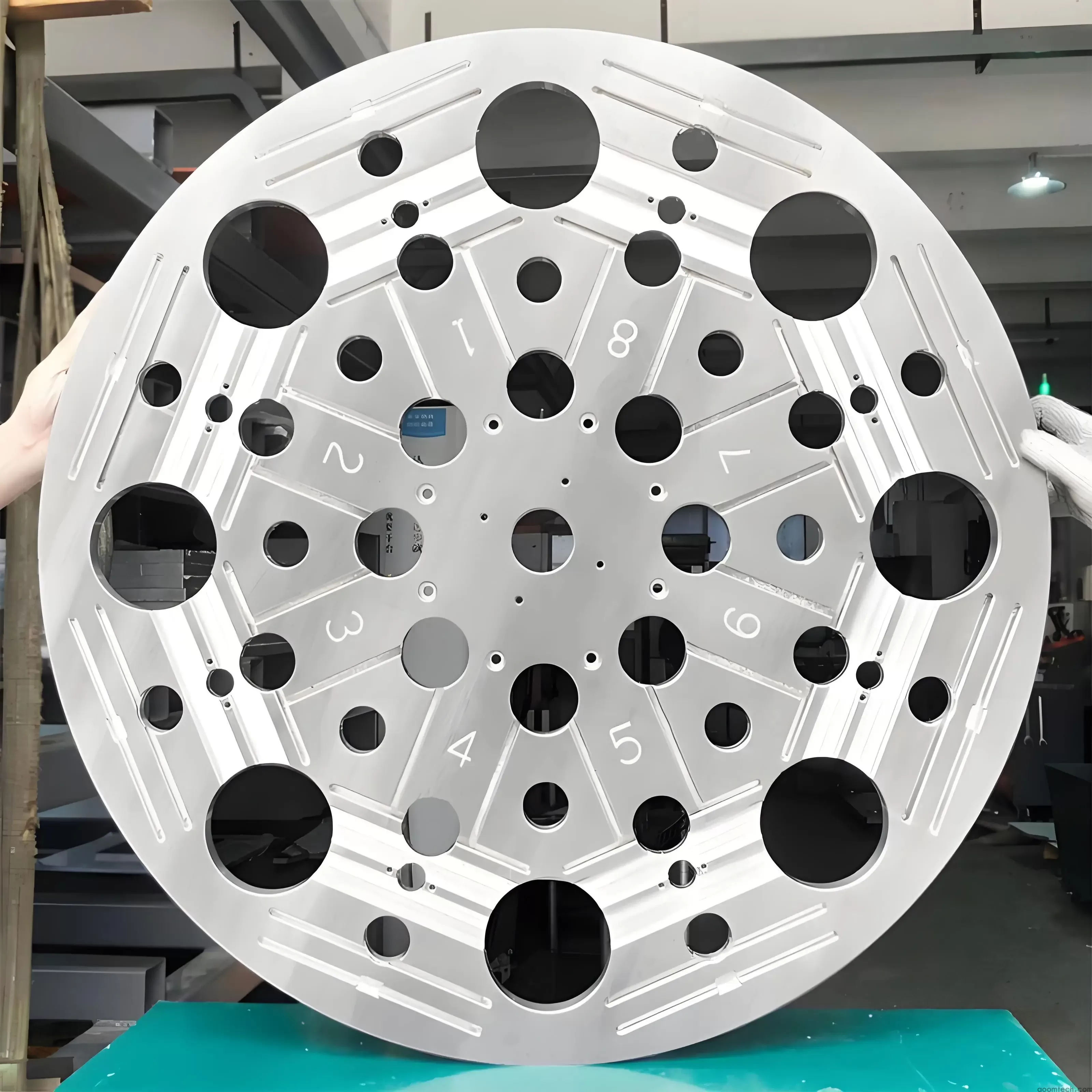

CNC Large Part Machining

As a leading CNC machining service provider, AOOM Technology specializes in precision manufacturing of large-scale components for industries ranging from aerospace to energy. This article explores the technical challenges and solutions in CNC large part machining.

Understanding CNC Large Part Machining

CNC large part machining refers to the manufacturing of components typically exceeding 1 meter in any dimension, requiring specialized equipment and expertise. At AOOM, we utilize gantry mills and horizontal machining centers with work envelopes up to 5m×3m×2m to handle such projects.

Key Challenges in Large Part Machining

1. Material Stability: Large metal parts are prone to thermal deformation during machining

2. Tool Path Optimization: Requires advanced CAM programming to maintain precision

3. Vibration Control: Our machines feature active damping systems for superior surface finish

AOOM's Technical Advantages

Our facility features:

- 5-axis simultaneous machining capability for complex geometries

- On-machine inspection with laser trackers

- Temperature-controlled workshop (±1°C) for thermal stability

- Rigorous QA process including CMM verification

Industry Applications

We regularly manufacture:

- Aerospace structural components

- Energy sector turbine housings

- Industrial machinery bases and frames

- Transportation equipment large assemblies

Why Choose AOOM for Your Large Part Needs

With 15+ years of experience in CNC machining, we offer:

1. One-stop solution from design to finished product

2. Tight tolerances (±.05mm achievable)

3. Material expertise including aluminum, steel, and titanium alloys

4. ISO 9001 certified quality management

Contact our engineering team at AOOM Technology to discuss your large-scale machining project requirements and receive a customized solution proposal.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F