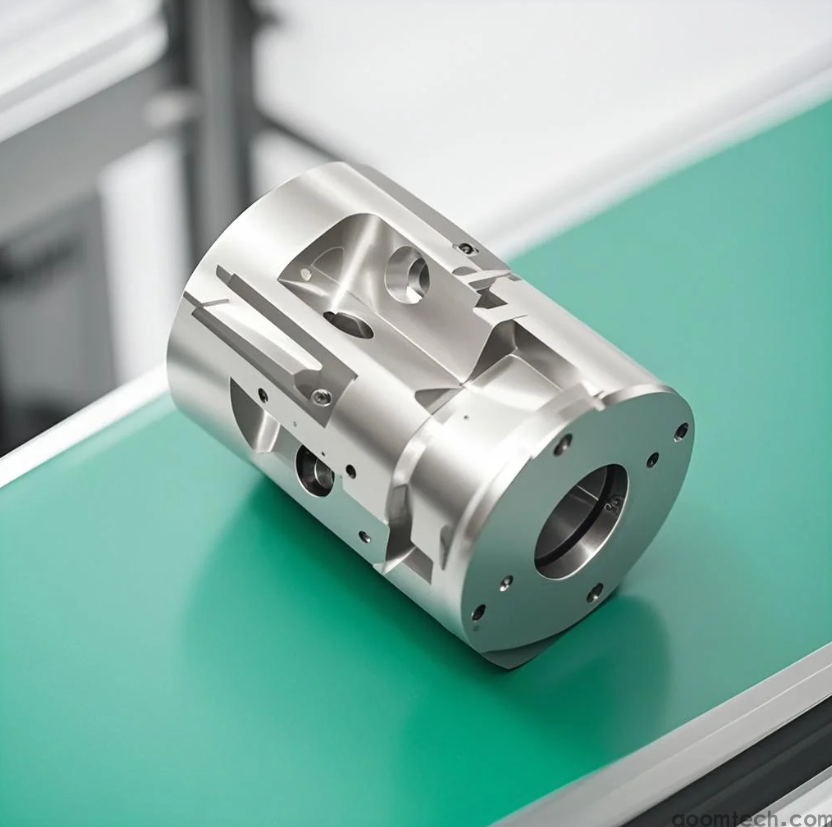

CNC Security Parts Machining: Precision Manufacturing for Safety-Critical Applications

In today's security-conscious world, CNC security parts machining plays a vital role in producing reliable components for surveillance systems, access control devices, and protective equipment. As a professional CNC machining service provider, AOOM Technologies specializes in manufacturing high-precision security components that meet stringent industry standards.

Why Choose CNC Machining for Security Components?

Security applications demand components with exceptional dimensional accuracy, durability, and consistent quality. CNC machining offers the perfect solution with its ability to produce complex geometries from various materials while maintaining tight tolerances (±.005mm). Our 5-axis CNC machines can create intricate security parts including camera housings, lock mechanisms, and sensor components with superior surface finishes.

Materials We Process for Security Applications

We machine a wide range of materials suitable for security parts:

- Aluminum alloys (6061, 7075) for lightweight durability

- Stainless steel (303, 304, 316) for corrosion resistance

- Brass and bronze for locking mechanisms

- Engineering plastics (PEEK, Delrin) for insulating components

AOOM's Capabilities in Security Parts Manufacturing

Our 15,000㎡ facility houses advanced CNC machining centers equipped with:

- High-speed machining up to 20,000 RPM

- Automatic tool changers with 30+ tool capacity

- In-process inspection systems

- Surface treatment options (anodizing, plating, powder coating)

With ISO 9001 certification and strict quality control protocols, AOOM Technologies delivers security components that meet IP ratings and other industry-specific requirements. Our engineering team works closely with clients to optimize designs for manufacturability without compromising security performance.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F