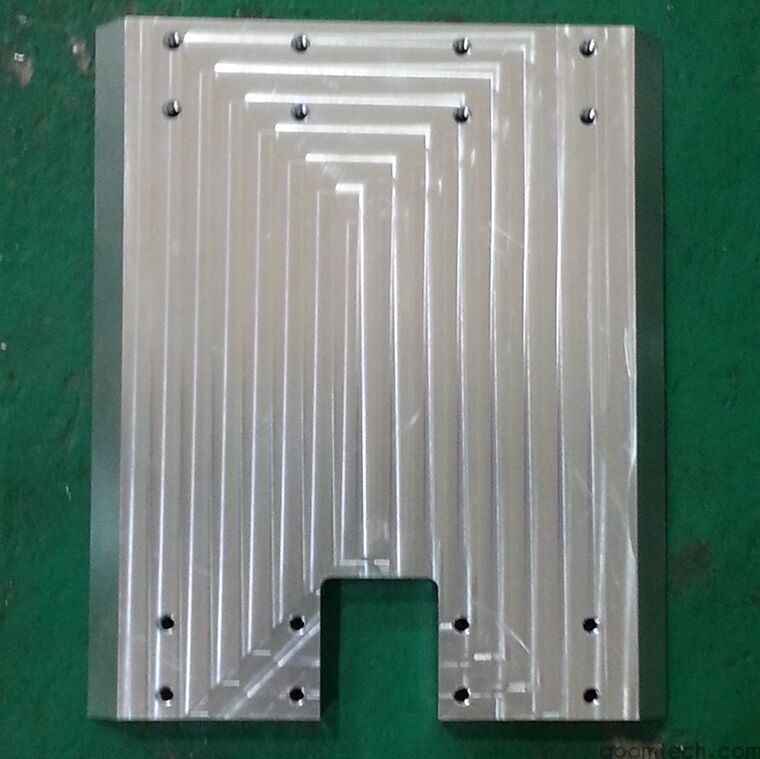

CNC Stainless Steel Plate Processing Technology

As a professional CNC machining service provider, AOOM Technology specializes in delivering high-precision CNC stainless steel plate processing solutions for industries ranging from aerospace to medical equipment. This article will explore the key aspects of this advanced manufacturing technique.

What is CNC Stainless Steel Plate Processing?

CNC stainless steel plate processing refers to the computer-controlled machining of stainless steel plates using specialized cutting tools. This technology enables the production of complex components with tight tolerances (typically ±.005 inches) and excellent surface finishes (reaching Ra .8μm). At AOOM, we employ 5-axis CNC machines capable of handling plates up to 200×100×150mm in size.

Key Advantages of Our CNC Stainless Steel Machining

Our CNC processing technology offers several distinct benefits:

- Superior dimensional accuracy for critical applications

- Excellent repeatability for mass production

- Ability to machine various stainless steel grades (304, 316, 17-4PH, etc.)

- Reduced material waste through optimized tool paths

Applications Across Industries

Our CNC machined stainless steel components serve multiple sectors:

- Medical: Surgical instruments and implant components

- Food processing: Hygienic equipment parts

- Automotive: Precision engine components

- Energy: Corrosion-resistant parts for harsh environments

With ISO 9001-certified quality control and 15+ years of machining experience, AOOM Technology guarantees reliable CNC stainless steel plate processing services. Contact us at www.aoomtech.com for your custom machining requirements.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F