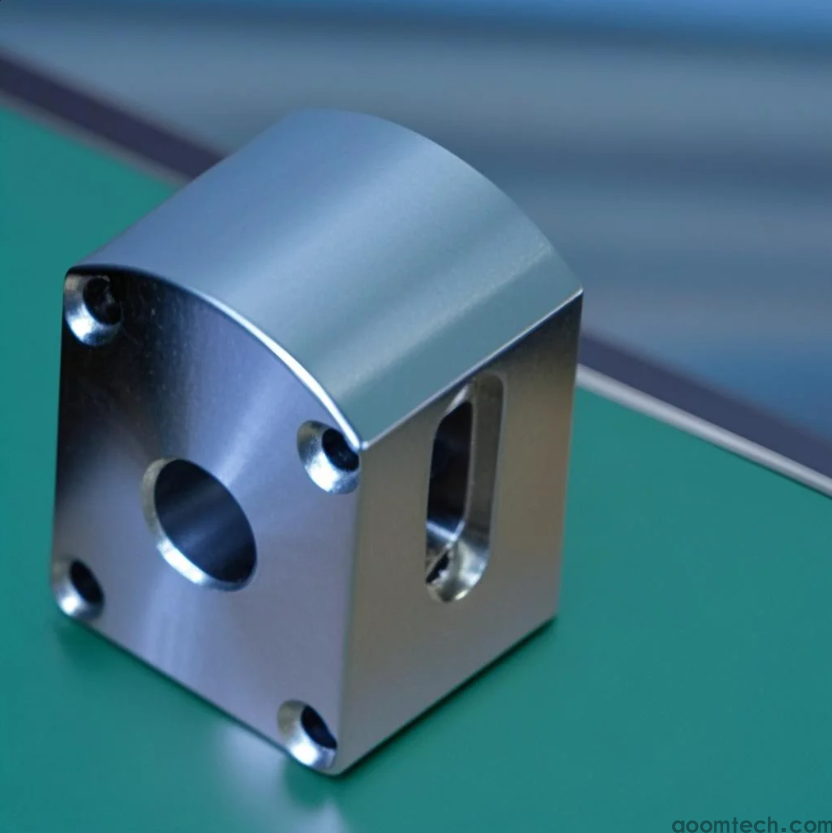

CNC Machining Tungsten Steel Parts

As a leading CNC machining service provider, AOOM Technology specializes in manufacturing precision tungsten steel parts for industries requiring extreme durability and tight tolerances. Our advanced CNC systems and engineering expertise deliver components that outperform standard metal alternatives.

Why Choose Tungsten Steel for CNC Machining?

Tungsten steel (also called cemented carbide) offers unparalleled hardness (up to 92 HRA) and wear resistance, making it ideal for cutting tools, molds, and high-stress industrial components. Our CNC machining processes overcome tungsten's brittleness through:

- Specialized toolpath programming to prevent chipping

- High-rigidity machine tools with vibration damping

- Custom coolant strategies for thermal management

Our Tungsten Steel Machining Capabilities

AOOM's 5-axis CNC centers achieve ±.005mm tolerances on tungsten steel parts, supported by:

- Material preparation: HIP treatment for porosity reduction

- Machining: Diamond-coated tools and EDM for complex geometries

- Finishing: Micro-blasting and precision grinding

Industry Applications

We manufacture mission-critical components for:

- Aerospace: Fuel system valves, turbine components

- Medical: Surgical tooling, implant molds

- Automotive: Wear-resistant bushings, forming dies

Why Partner with AOOM Technology?

With ISO 9001-certified production and DFM support, we ensure your tungsten steel components meet exact specifications while optimizing cost-efficiency. Our engineers collaborate closely to solve unique material challenges.

Visit aoomtech.com to request a free project evaluation or discuss your CNC machining requirements with our technical team.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F