CNC Machining Service Quotation

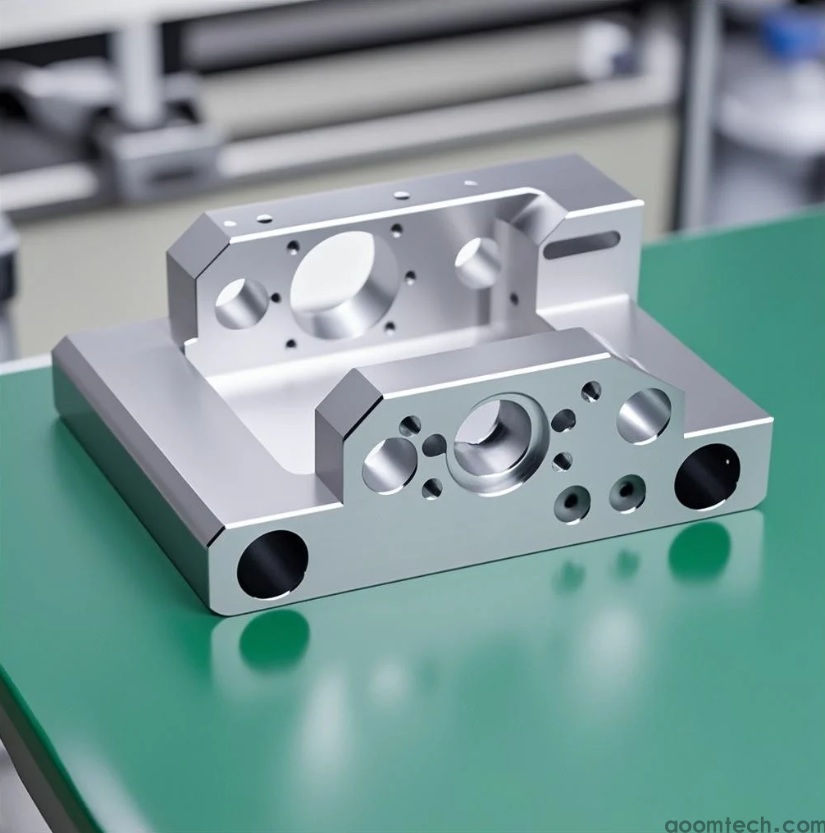

When sourcing CNC machining services, obtaining accurate and competitive quotations is a top priority for procurement professionals and engineers. As a trusted CNC machining service provider, AOOM Technology explains the key factors affecting pricing and how we deliver transparent cost structures.

Factors Influencing CNC Service Quotes

1. Material Selection: Aluminum, steel, titanium, and plastics have varying raw material costs and machining characteristics.

2. Part Complexity: Intricate geometries requiring 5-axis machining or tight tolerances increase production time.

3. Surface Finishing: Additional processes like anodizing or powder coating incur extra costs.

4. Order Volume: Bulk orders typically benefit from economies of scale.

AOOM's Competitive Advantages

• Advanced Equipment: Our 50+ CNC mills and lathes ensure efficient production

• ISO 9001 Certified: Consistent quality control reduces scrap rates and rework costs

• DFM Analysis: Free design optimization to lower your CNC machining service quotation

• Transparent Pricing: Detailed breakdowns with no hidden fees

How to Get Your Custom Quote

Submit your CAD files through our website (www.aoomtech.com) or email sales@aoomtech.com. Our engineers typically respond within 4 business hours with:

- Material recommendations

- Tolerance analysis

- Lead time options

- Volume pricing tiers

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F