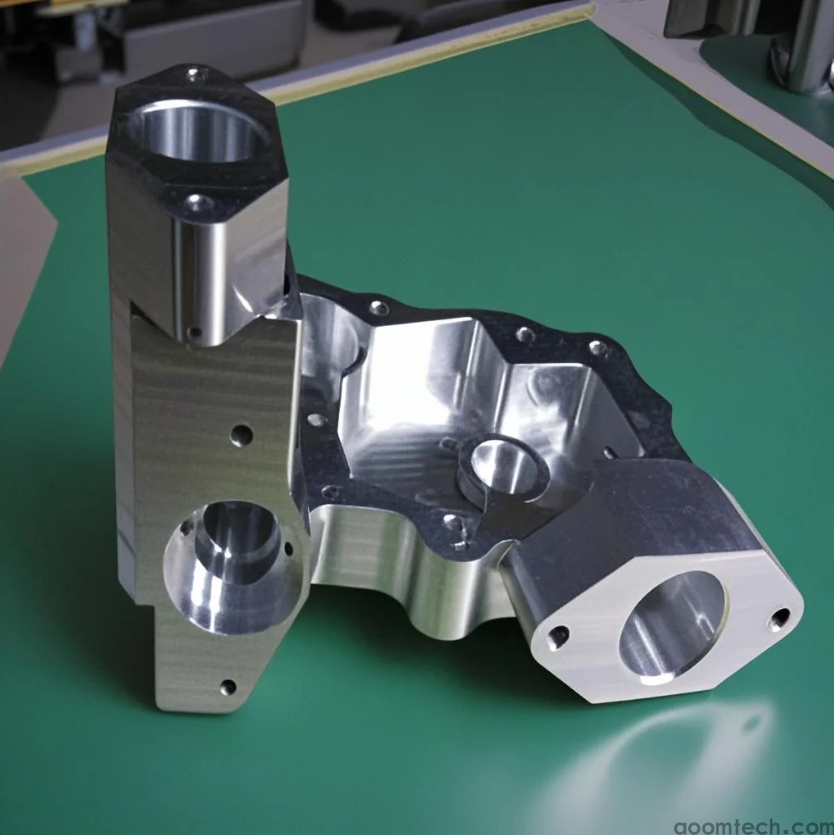

CNC Machining Engine Parts

As a leading CNC machining service provider, AOOM Technologies specializes in manufacturing precision engine components for automotive, aerospace, and industrial applications. This article explores the critical aspects of producing high-performance engine parts through advanced CNC processes.

Why Choose CNC Machining for Engine Components?

Modern engines demand extreme precision and durability. Our 5-axis CNC machines achieve tolerances within ±.005mm, ensuring perfect fitment for pistons, cylinder heads, crankshafts, and turbocharger housings. The automated process eliminates human error while maintaining consistent quality across mass production.

Material Selection for Engine Parts

We machine engine parts from aerospace-grade aluminum alloys, stainless steel, titanium, and high-temperature nickel alloys. Our material engineers help select optimal metals based on thermal expansion coefficients, weight requirements, and combustion chamber pressures.

AOOM's Quality Assurance Process

Every component undergoes three-stage inspection: 1) In-process CMM verification 2) Surface roughness testing 3) Final performance simulation. Our ISO 9001-certified facility maintains complete traceability from raw material to finished product.

Advantages of Partnering with AOOM

• 15+ years of engine parts manufacturing expertise

• 98% on-time delivery record

• Prototype-to-production solutions

• Competitive pricing for OEM quantities

Discover how our CNC machining capabilities can enhance your engine performance. Visit aoomtech.com to request a free design consultation and quote today.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F