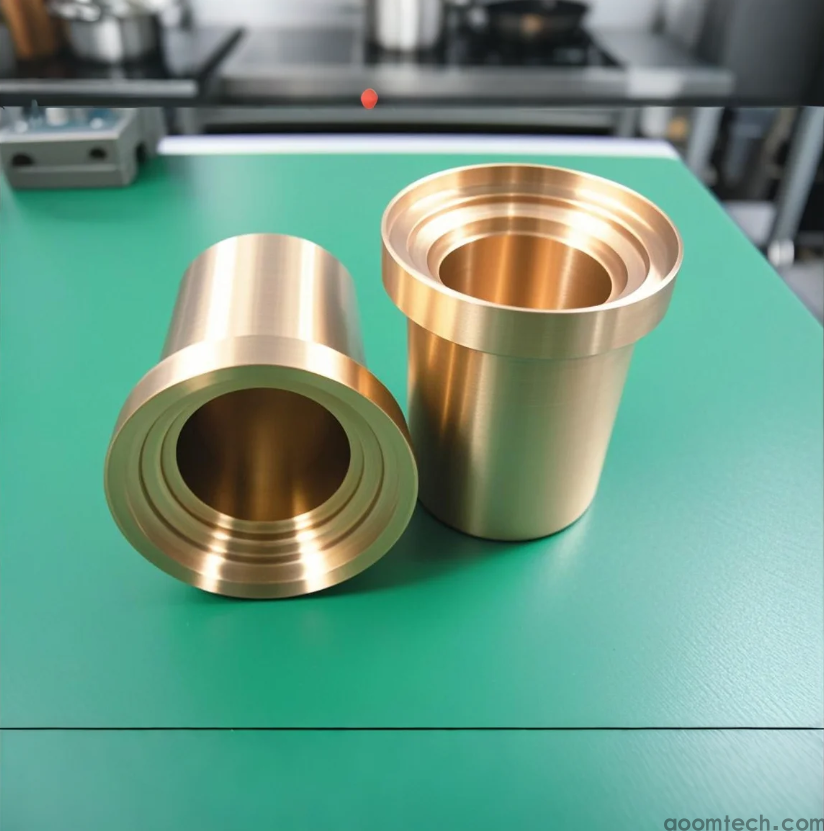

CNC Brass Machining Process

As a leading CNC machining service provider, AOOM Technologies specializes in precision brass component manufacturing. This article explores the technical nuances of CNC brass machining to help procurement professionals and engineers make informed decisions.

Understanding CNC Brass Machining

Brass, an alloy of copper and zinc, offers excellent machinability and corrosion resistance. The CNC brass machining process involves computer-controlled removal of material from brass workpieces to create precise components for industries like plumbing, electrical, and automotive.

Key Advantages of Our CNC Brass Machining

1. Precision Engineering: Our 5-axis CNC machines achieve tolerances up to ±.005mm

2. Surface Finish Options: From Ra .8μm mirror finishes to textured surfaces

3. Material Expertise: Machining all brass grades including C36000, C26000, and C28000

4. Cost Efficiency: Optimized tool paths reduce material waste by up to 30%

Technical Process Flow

Our standardized workflow ensures consistent quality:

1. Material Selection → 2. CAD/CAM Programming → 3. Machine Setup → 4. Precision Machining → 5. Deburring → 6. Quality Inspection → 7. Surface Treatment → 8. Final Packaging

Why Choose AOOM Technologies?

With 15+ years of CNC machining experience, we offer:

• ISO 9001:2015 certified production facilities

• 24/7 technical support for urgent projects

• Customized solutions from prototyping to mass production

• Strict compliance with ASTM B16/B36 standards

Contact us at www.aoomtech.com for your brass machining projects. Our engineering team provides DFM analysis and cost optimization suggestions within 24 hours.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F