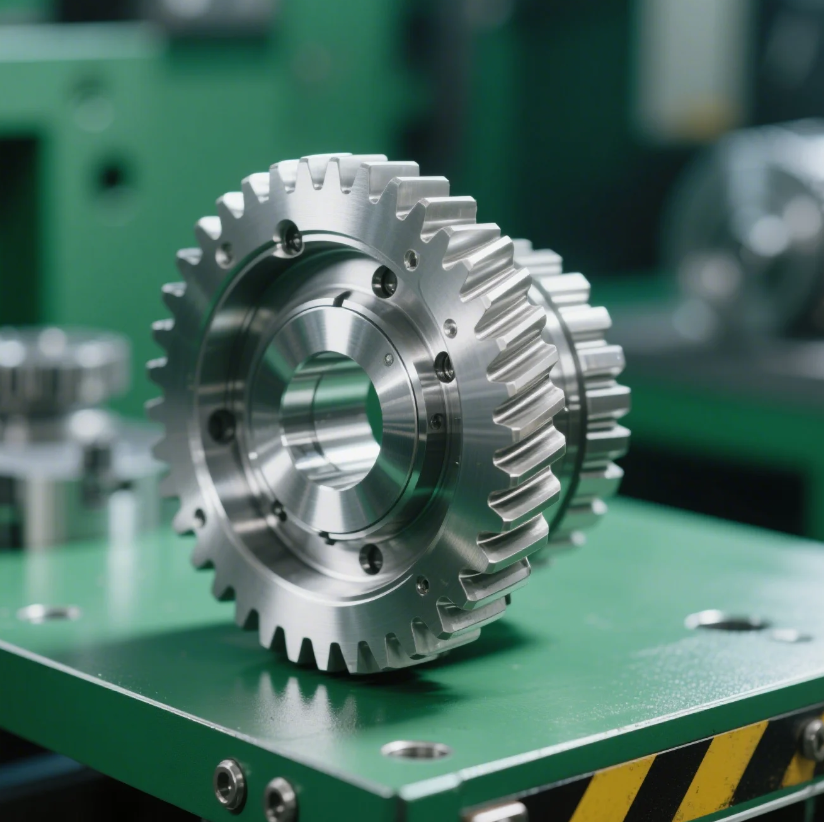

CNC Lathe Machining for Gears

Views :

Update time : 2025-06-06

In precision manufacturing, CNC lathe machining for gears stands as a critical process for industries requiring high-tolerance rotational components. AOOM Technology specializes in delivering gear solutions that meet aerospace, automotive, and industrial equipment standards.

Why Choose CNC Lathe for Gear Manufacturing?

Modern CNC lathe machining enables micron-level accuracy in gear tooth profiling, surpassing traditional hobbing methods. Our 5-axis CNC lathes achieve:

- ±.005mm dimensional tolerance

- Ra .8μm surface finish

- 100% CMM inspection compatibility

Materials and Gear Types We Process

From spur gears to helical designs, we machine:

- Steel alloys (414, 434)

- Aluminum (6061-T6, 7075)

- Brass and bronze

- Engineering plastics (PEEK, Delrin)

AOOM's Technical Advantages

Our CNC gear machining capabilities include:

- Dual-turret lathes for simultaneous OD/ID machining

- Live tooling for cross-drilled holes

- Automated post-process deburring

- ISO 1328-1:2013 compliant quality control

Visit aoomtech.com to request a free DFM analysis for your gear project, backed by our 15-year CNC machining expertise.

Related News

Read more >>

CNC Machining Parts Customizat

CNC Machining Parts Customizat

07 .07.2025

As a professional CNC machining service provider, AOOM Technology specializes in delivering high-pre...

Recommendation for CNC Precisi

Recommendation for CNC Precisi

07 .07.2025

When it comes to sourcing high-quality Manufacturers of CNC Precision Parts and Components, business...

CNC Precision Machining Custom

CNC Precision Machining Custom

07 .07.2025

As a leading CNC precision machining service provider, AOOM Technology specializes in manufacturing ...

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F

07 .06.2025

As a leading CNC machining service provider, AOOM Technologies specializes in manufacturing high-pre...