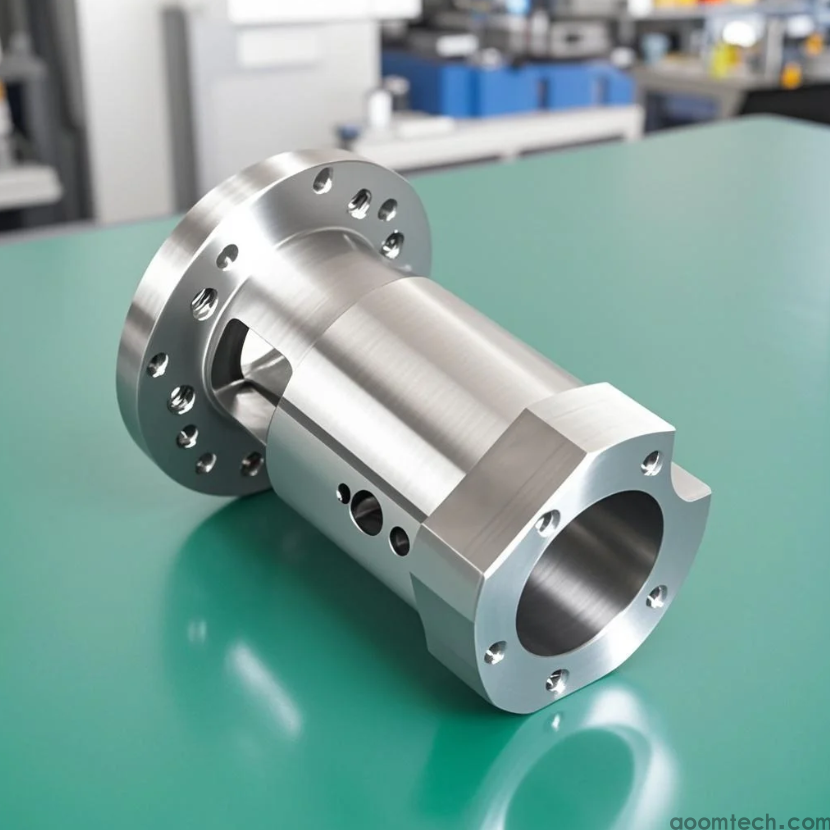

CNC Machining Precision Parts Advantages

In modern manufacturing, CNC machining precision parts has become the gold standard for industries demanding exceptional accuracy and repeatability. As a leading CNC machining service provider, AOOM Technology specializes in delivering high-precision components that meet the most stringent quality requirements.

Unmatched Accuracy and Consistency

The primary advantage of CNC precision part machining lies in its ability to maintain tolerances within ±.005mm consistently. Our 5-axis CNC machines at AOOM Technology utilize advanced positioning systems and cutting tools to achieve this level of precision, ensuring every part meets exact specifications batch after batch.

Superior Material Versatility

From aerospace-grade aluminum to medical-grade titanium, our CNC machining services handle diverse materials with equal precision. This flexibility allows engineers to select optimal materials for their specific applications without compromising on manufacturing capabilities.

Enhanced Production Efficiency

CNC automation significantly reduces production time compared to manual machining. Our optimized CNC precision machining processes at AOOM Technology can complete complex parts in single setups, minimizing human intervention while maximizing output quality.

Cost-Effective for Complex Geometries

Intricate designs that would be prohibitively expensive with conventional methods become economically viable with CNC machining. Our team excels at transforming complex CAD models into physical parts with perfect dimensional accuracy.

Why Choose AOOM Technology?

With ISO 9001-certified facilities and a team of seasoned engineers, AOOM Technology delivers CNC machined parts that exceed industry standards. Our end-to-end quality control ensures every component meets your exact requirements, supported by comprehensive DFM analysis and surface treatment options.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F