CNC Machining Parts Company: Which One is the Best?

When sourcing precision components, selecting the right CNC machining parts company directly impacts product quality, cost efficiency, and project timelines. As a CNC manufacturing specialist with 15+ years in aerospace and medical device production, I'll break down the critical selection criteria to help technical buyers make informed decisions.

Key Evaluation Criteria for Top-Tier CNC Suppliers

1. Technical Capability: Verify ISO 9001/AS910 certifications and maximum tolerance accuracy (we maintain ±.005mm at AOOM Tech)

2. Material Expertise: Look for multi-material experience (aluminum, titanium, PEEK, etc.) with proper heat treatment knowledge

3. Production Capacity: Assess simultaneous 3/4/5-axis machining capabilities and batch production scalability

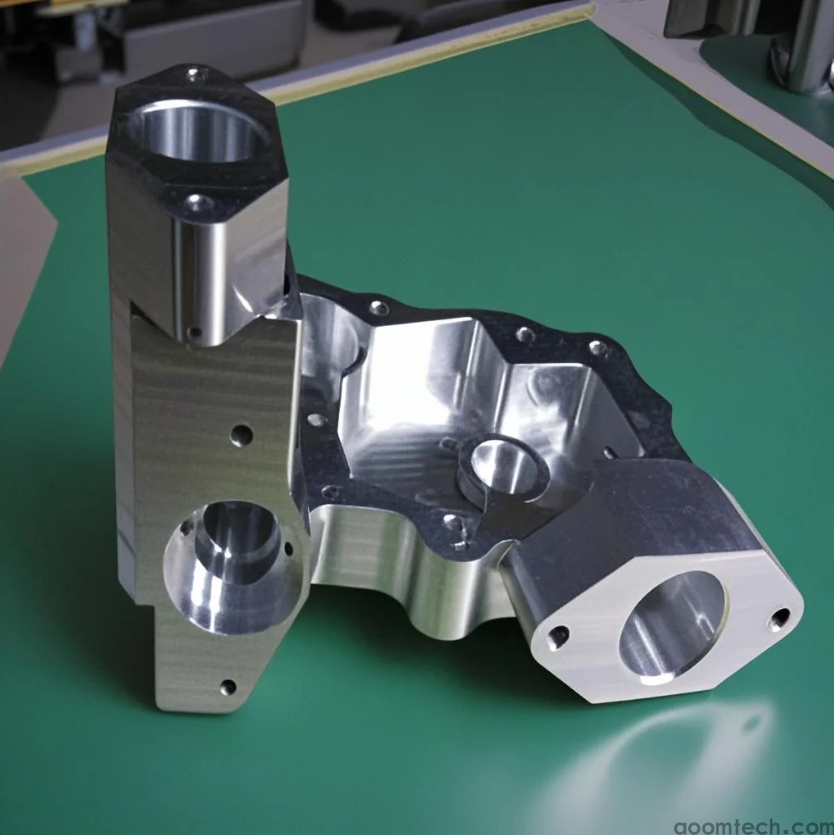

Why AOOM Tech Stands Out in CNC Manufacturing

Our CNC machining services combine German-engineered DMG Mori equipment with proprietary quality control protocols:

- 98% on-time delivery rate across 200+ annual projects

- Full-spectrum post-processing (anodizing, powder coating, EDM)

- Dedicated engineering support from DFM analysis to final inspection

Industry-Specific Solutions

We specialize in high-value applications requiring precision CNC parts:

• Aerospace: FAA-compliant structural components

• Medical: Biocompatible implant-grade machining

• Automotive: IATF 16949 certified production

Request a free project evaluation at www.aoomtech.com to experience our data-driven manufacturing approach with guaranteed dimensional reports for every shipment.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F