What Precision Can CNC 3-Axis Machining Achieve?

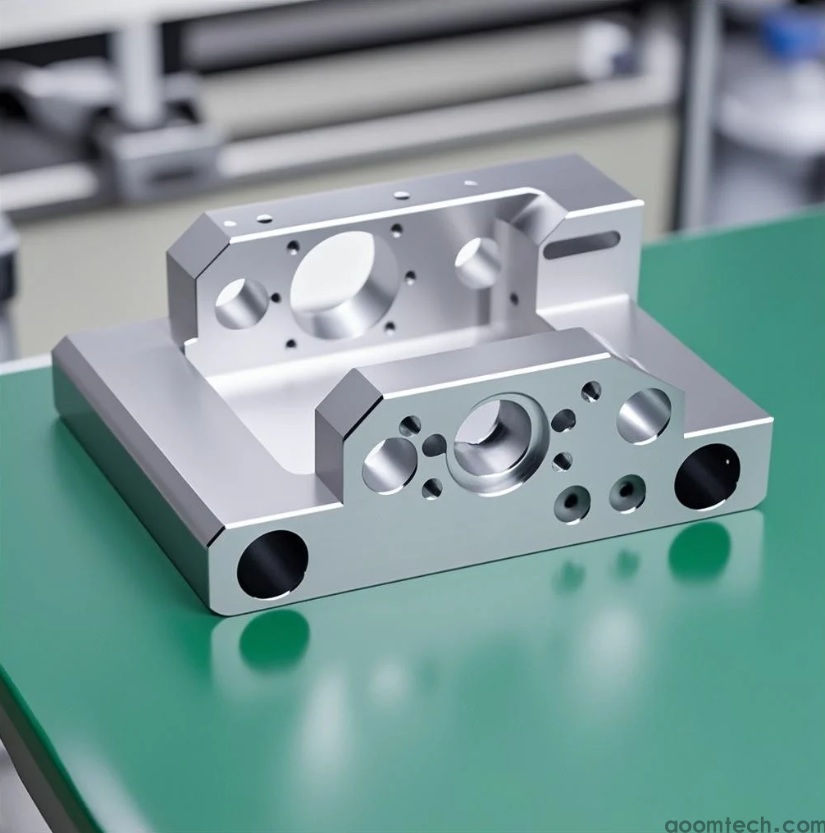

As a professional CNC machining service provider, AOOM Technology understands that precision is the cornerstone of manufacturing excellence. When clients inquire about CNC 3-axis machining capabilities, they are typically seeking clarity on achievable tolerances and surface finishes for their projects.

Understanding CNC 3-Axis Machining Precision

Standard 3-axis CNC machines can typically maintain tolerances of ±.005" (±.127mm) for most materials, with some high-performance machines achieving ±.001" (±.025mm) under optimal conditions. The actual precision depends on multiple factors including machine calibration, tooling quality, material characteristics, and operator expertise.

Key Factors Affecting Machining Accuracy

1. Machine Rigidity: Our German and Japanese CNC equipment maintains exceptional stability

2. Tooling Selection: We use premium carbide end mills from leading brands

3. Temperature Control: Climate-controlled workshop prevents thermal expansion

4. Measurement Systems: Mitutoyo CMM machines verify part dimensions

AOOM's Precision Capabilities

Through our ISO 9001-certified processes, we consistently deliver:

- Standard tolerance: ±.005" (±.127mm)

- High-precision tolerance: ±.001" (±.025mm)

- Surface finishes down to Ra .8μm (32μin)

Our engineering team can recommend optimal machining strategies to balance precision requirements with cost efficiency.

Applications of Precision 3-Axis Machining

This technology serves industries requiring tight tolerances:

• Aerospace components

• Medical device prototypes

• Automotive parts

• Industrial automation systems

At AOOM Technology, we combine advanced equipment with decades of machining expertise to deliver precision components that meet your exact specifications. Contact our engineering team to discuss your project's specific requirements.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F