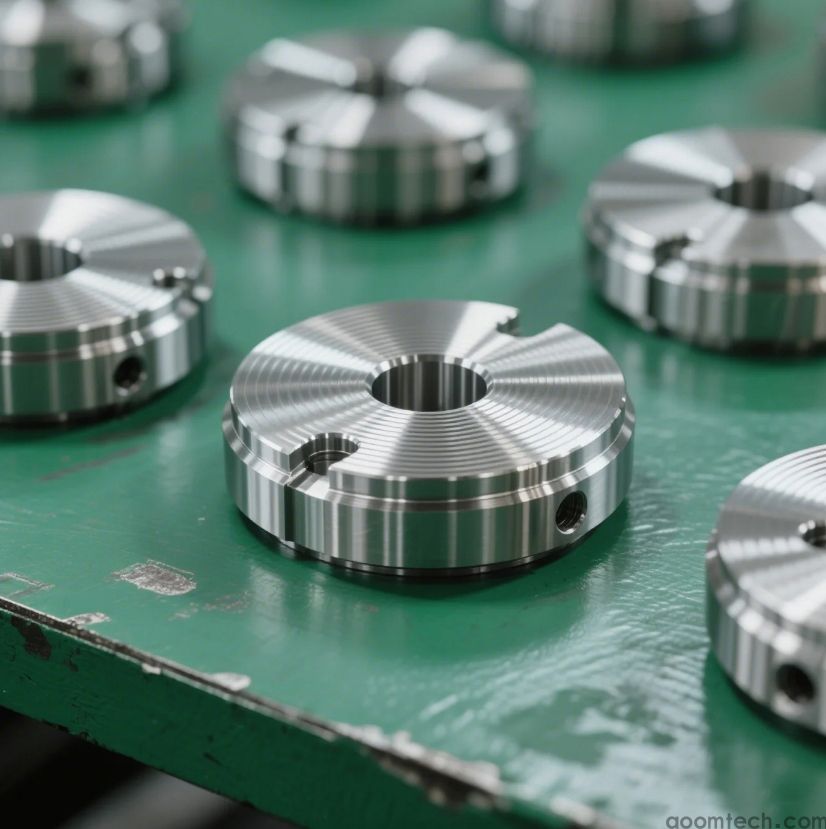

Overcoming Common Challenges in CNC Stainless Steel Machining: A Practical Guide

Feeling frustrated with tool breakage, poor surface finishes, or just can't seem to hit the right tolerances when machining stainless steel? You're not alone. 😩 Stainless steel is a beast—it's tough, it work-hardens, and it can be downright unforgiving. But what if you could understand exactly why it acts the way it does and turn that knowledge into flawless parts? Let's break down the real-world hurdles and find some practical solutions, together.

Why is Stainless Steel So Tricky to Machine?

First off, let's talk about the elephant in the room. Stainless steel isn't just one material; it's a family, and some members are more difficult than others. The core issue lies in its properties. It's designed to be strong and resist wear, which is great for the final product but a headache for machining. Its tendency to work-harden is a big part of the problem. As you cut it, the area you're working on becomes harder, which then wears down your tool faster, leading to a vicious cycle of poor quality and broken tools. However, it's not an impossible task, it just demands more respect than other metals like aluminum.

Conquering the Work-Hardening Nightmare 🛠️

This is probably the number one question we get. You're making a cut, and suddenly, the material seems to fight back. That's work-hardening in action.

So, what can you do?

- Keep a Constant Feed Rate: Never, ever pause the tool during a cut. A continuous, aggressive feed ensures you're cutting under the hardened layer created by the previous tooth, rather than rubbing against it and making it harder.

- Use Sharp Tools, Always: A slightly dull tool is a work-hardening machine. It rubs more than it cuts. I make it a habit to inspect tools regularly—it saves a lot of trouble down the line.

- Optimize Your Speeds and Feeds: While general guidelines exist, the perfect balance often depends on your specific machine and stainless grade. This is an area where the specific interaction between tool coating and material chemistry can get really complex, and honestly, sometimes it feels more like an art than a science.

Choosing the Right Tool for the Job

Not all cutting tools are created equal, especially when your opponent is stainless steel. Using the wrong tool is like trying to cut a steak with a butter knife.

My go-to choices are:

- Geometry is Key: Look for tools with a positive rake angle. This shears the material more cleanly, reducing cutting forces and heat.

- Material Matters: Carbide tools are pretty much the standard here. For tougher grades, you might look into advanced coatings, though the cost-benefit analysis for each job can be a real head-scratcher.

Rigidity is Non-Negotiable: Ensure your tool holder and setup are as rigid as possible. Any vibration or chatter will kill your tool and ruin the surface finish.

Taming the Heat: Coolant and Chip Control 🔥

Heat is the enemy of both your tool and your part. Stainless steel has poor thermal conductivity, meaning the heat from cutting doesn't dissipate easily—it stays right at the cutting edge.

Effective strategies include:

- Flood Coolant is Your Best Friend: A good, high-quality coolant is not just for cooling; it also lubricates and helps wash away chips. This is one area I never try to cut corners on.

- Watch Your Chips: The ideal chip should be tightly curled and silverish. Long, stringy chips are a bad sign—they indicate incorrect parameters and can wreak havoc, wrapping around your tool and workpiece. Proper chip evacuation is critical.

Though, having said that, I've seen some setups using compressed air or even MQL (Minimum Quantity Lubrication) with success, which perhaps suggests that the "flood coolant always" rule isn't as absolute as we once thought.

A Quick Word on Material Grades

Not all "stainless" is the same. 304 is common but can be gummy. 316 has molybdenum, making it even tougher. Then you have the "free-machining" grades like 303, which have additives like sulfur to make your life easier. Knowing your specific material is half the battle. If you have the flexibility, choosing a more machinable grade from the start can save countless hours and dollars.

At the end of the day, mastering CNC stainless steel machining is a journey of continuous tweaking and learning. It's about listening to your machine, watching your chips, and not being afraid to make a small change to see a big result. The satisfaction of pulling out a perfect, shiny stainless part? That makes all the trouble worthwhile. ✨

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How Much Does Small Batch CNC

How Much Does Small Batch CNC

How to Prevent Deformation in

How to Prevent Deformation in