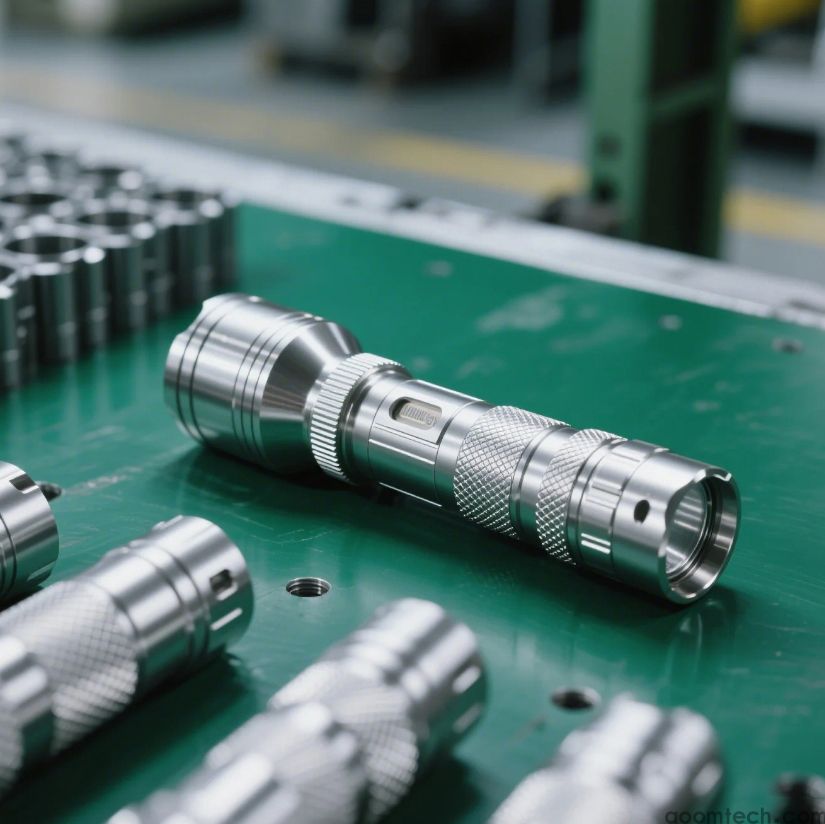

What Tolerance Can You Achieve with CNC Bar Machining? A Practical Guide

Hey there, fellow engineers and procurement pros! 👋 Ever found yourself staring at a technical drawing, wondering if your CNC bar machining supplier can actually hit those tiny tolerance numbers? You're not alone. I've been in those meetings where everyone nods, but deep down, there's that nagging question: "What's realistically achievable?" Let's cut through the marketing fluff and talk real numbers. 🤔

So, What's the Real Deal with CNC Bar Machining Accuracy?

First things first, let's answer the big question. For most standard CNC bar machining jobs, you can generally expect to hold tolerances around ±.025 mm to ±.05 mm (±.001" to ±.002"). That's about the thickness of a human hair! But—and this is a big but—this isn't a guarantee for every single part. It depends on a whole bunch of factors that we'll dig into next. I've seen shops consistently hit these numbers on aluminum and brass, but when it comes to some tricky plastics or super-alloys, the story can change.

What Factors Actually Mess With Your Machining Precision?

It's never just about the machine. Here are the usual suspects that can make or break your tolerance goals:

✅ The Material Itself: Some materials are just easier to work with. Aluminum is pretty forgiving and stable, making it a dream for tight tolerances. But something like stainless steel? It can be a bit of a diva, moving around with heat and stress. The exact way different alloys behave under the cutting tool is something I'm still wrapping my head around.

✅ Machine Condition and Age: A brand-new, high-end Swiss-type lathe is a precision beast. An older, worn-out machine might struggle. It's that simple.

✅ The Length of the Part: This is a big one that often gets overlooked. Trying to hold a tight tolerance on a long, skinny bar? That's much harder than on a short, stubby part. Vibration and deflection become your enemies.

How Can You Help Your Supplier Hit Those Tighter Tolerances?

Believe it or not, you have a role to play too! Here's how you can set your project up for success:

🔧 Be Smart with Your Tolerances: Don't just call out super tight tolerances everywhere on the drawing. I always ask my team, "Does this surface really need to be that precise?" Only apply tight tolerances to critical features. This saves cost and headache.

🔧 Talk to Your Machinist Early: Get their input during the design phase. They might suggest a small change that makes the part much easier and cheaper to machine accurately.

🔧 Choose the Right Material: If high precision is your goal, maybe an aluminum grade is a better bet than that specific stainless steel you had in mind. Discuss the options.

Is "More Precision" Always the Right Answer?

Here's my two cents, from seeing hundreds of projects. Chasing the absolute tightest tolerance possible is often a trap. 🤯 The cost doesn't increase linearly; it goes up like a hockey stick. That last .01 mm of precision might double your part cost. You have to ask: What does the function of the part actually require? Sometimes, "good enough" is not just good enough—it's the smartest business decision. Perfection can be the enemy of profitability.

That being said, for critical components in aerospace or medical devices, that extreme precision is non-negotiable. But for a lot of general applications, perhaps it's overkill. The real skill is in knowing the difference.

From my experience, the best results come from a partnership. It's not just about pushing a supplier for the lowest price and highest precision. It's about clear communication, realistic expectations, and understanding the trade-offs. I've found that being upfront about your budget and performance needs leads to a much smoother process and a better final product. 🚀 Just something to think about for your next project.

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How Much Does Small Batch CNC

How Much Does Small Batch CNC

How to Prevent Deformation in

How to Prevent Deformation in