CNC Product Processing: Which Company is the Best?

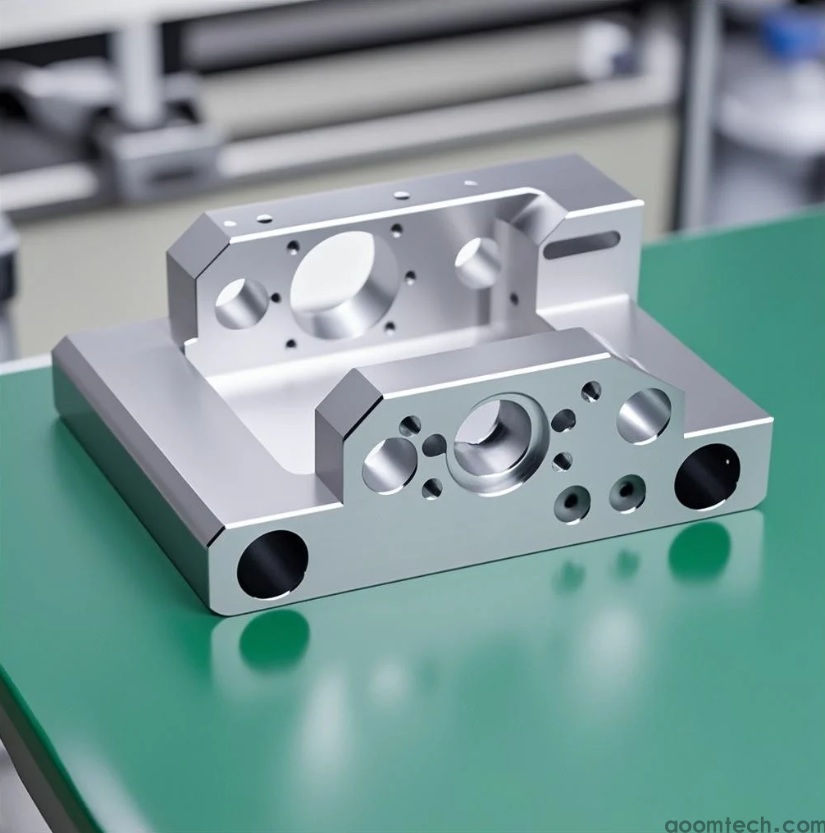

When it comes to CNC product processing, choosing the right manufacturer is crucial for ensuring precision, efficiency, and cost-effectiveness. As a professional CNC machining service provider, AOOM Technology specializes in delivering high-quality CNC product processing solutions tailored to meet diverse industrial needs. This article explores what makes a reliable CNC machining partner and why AOOM stands out in the industry.

What to Look for in a CNC Product Processing Company

Selecting the best CNC product processing manufacturer involves evaluating several key factors:

- Precision & Quality: The company must demonstrate exceptional accuracy (typically within ±.01mm) and rigorous quality control systems like ISO 9001 certification.

- Technical Capabilities: Look for advanced equipment (5-axis CNC machines, Swiss-type lathes), material expertise (aluminum, stainless steel, titanium, plastics), and surface treatment options.

- Industry Experience: Manufacturers with proven track records across aerospace, medical, automotive, and electronics sectors bring valuable insights.

- Customization: The ability to handle both prototyping and mass production with flexible solutions is essential.

Why Choose AOOM for CNC Product Processing?

AOOM Technology distinguishes itself through:

- Advanced Manufacturing Facility: Equipped with 30+ state-of-the-art CNC machines including 5-axis machining centers capable of complex geometries.

- Material Mastery: Expertise in machining over 50 materials from aluminum alloys to engineering plastics with optimal tooling strategies.

- Quality Assurance: Implemented a complete QC system with CMM inspection, surface roughness testing, and material certification.

- Rapid Turnaround: Prototype lead times as fast as 24 hours and production batches within 5-7 days for most standard orders.

- Cost Optimization: Value engineering services to recommend design modifications that reduce machining costs without compromising functionality.

Our CNC Product Processing Services

AOOM offers comprehensive CNC machining solutions:

- Precision Components: Shafts, gears, housings, and complex assemblies with tight tolerances

- Prototype Development: From concept to functional prototype with DFM feedback

- Small Batch Production: Economical solutions for 50-10,000 unit quantities

- Surface Finishing: Anodizing, plating, powder coating, and custom finishes

Industries We Serve

Our CNC product processing capabilities support:

- Aerospace: Flight-critical components meeting AS910 standards

- Medical: FDA-compliant surgical instruments and implantable devices

- Automotive: High-volume production of engine and transmission parts

- Electronics: Precision enclosures and heat sinks with EMI shielding

With over 12 years of CNC machining experience and hundreds of satisfied clients worldwide, AOOM Technology has established itself as a trusted partner for CNC product processing. Our combination of technical expertise, quality commitment, and customer-focused service makes us the ideal choice for your machining requirements.

Visit our website at www.aoomtech.com to explore our full capabilities or request a free project consultation with our engineering team.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F