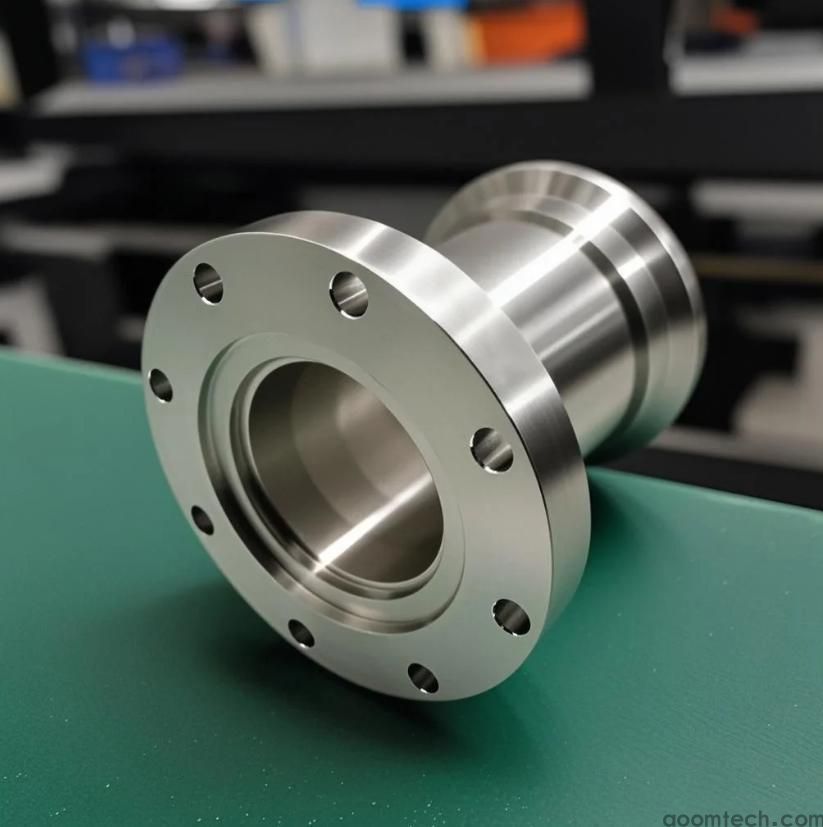

CNC Turning Customization Services for Precision Manufacturing

In modern manufacturing, CNC turning customization has become a cornerstone for industries requiring high-precision components. As a trusted provider at AOOM Technologies, we specialize in delivering tailored solutions that meet stringent quality standards while optimizing production efficiency.

What Is CNC Turning Customization?

CNC turning customization refers to the process of creating precision parts by rotating a workpiece while a cutting tool removes material. This method is ideal for producing cylindrical or conical shapes with tight tolerances (as low as ±.005mm). Our advanced CNC lathes at AOOM support multi-axis operations, enabling complex geometries like threads, grooves, and tapered features in materials ranging from aluminum alloys to titanium.

Key Advantages of Choosing AOOM for Custom CNC Turning

1. Material Expertise: We machine over 50+ metals/plastics, including challenging materials like Inconel and PEEK.

2. Precision Guarantee: ISO 9001-certified processes ensure dimensional accuracy up to IT6 grade.

3. Rapid Prototyping: 3-5 day lead times for prototype batches through our dedicated quick-turn service.

4. Surface Finish Options: From Ra .8μm mirror finishes to powder coating/anodizing.

Industries We Serve with Custom Turning Solutions

• Aerospace: Flight-critical components like hydraulic fittings

• Medical: FDA-compliant surgical instrument parts

• Automotive: High-volume fuel injection components

• Energy: Corrosion-resistant valve bodies for offshore applications

Our End-to-End Customization Workflow

1. Design Consultation: DFM analysis using SolidWorks/Creo software

2. Material Selection: Technical guidance on optimal grade selection

3. Process Planning: Toolpath optimization for minimal material waste

4. Quality Validation: CMM inspection with comprehensive reports

At AOOM Technologies, we combine German-engineered DMG MORI machines with 15+ years of machining expertise to deliver CNC turning customization that exceeds expectations. Request your free project evaluation today to experience precision manufacturing redefined.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C