CNC Mold Machining Process

Understanding CNC Mold Machining

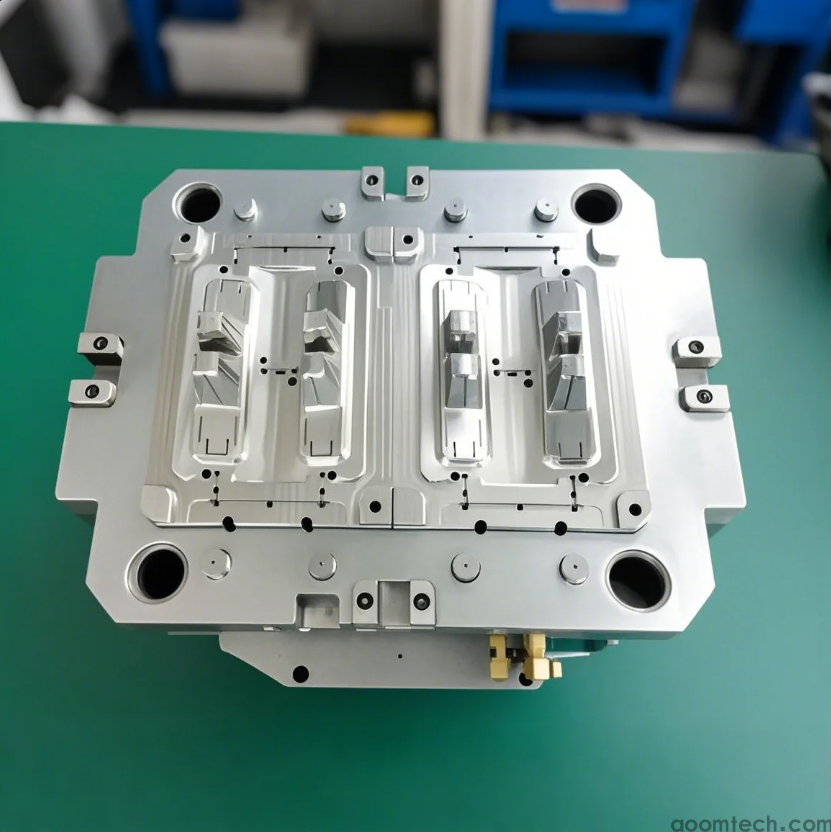

The CNC mold machining process is a critical manufacturing technique that transforms raw materials into precision molds used across various industries. At AOOM, we specialize in delivering high-quality CNC machined molds with exceptional accuracy and surface finish.

Step-by-Step Process Breakdown

1. Design and Programming: Our engineers create 3D CAD models and generate precise CNC toolpaths using advanced CAM software.

2. Material Selection: We carefully choose appropriate materials (typically tool steels or aluminum alloys) based on mold requirements.

3. Rough Machining: The initial shaping removes bulk material efficiently using high-power cutting tools.

4. Semi-Finishing: Intermediate operations bring the mold closer to final dimensions while maintaining proper tolerances.

5. Precision Finishing: The CNC machining process achieves final dimensions and surface quality through meticulous finishing passes.

6. Quality Inspection: We verify all critical dimensions using CMMs and other precision measuring instruments.

AOOM's Technical Advantages

Our facility features state-of-the-art 5-axis CNC machines capable of complex geometries with ±.01mm accuracy. We implement rigorous process controls throughout the CNC mold machining workflow to ensure consistent quality.

Applications Across Industries

CNC machined molds from AOOM serve diverse sectors including automotive, aerospace, medical devices, and consumer electronics. Our expertise covers injection molds, die casting molds, and stamping dies.

Why Choose AOOM for Your Mold Manufacturing

With extensive experience in CNC mold production, AOOM offers competitive lead times, cost-effective solutions, and technical support throughout your project lifecycle. Visit our website at https://www.aoomtech.com/ to explore our capabilities and request a quote.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C